With my background in performance automotive engines, I could not resist putting the EJ22 heads on my flow bench to verify airflow rates. I was also interested in comparing exhaust port flow between the cylinders with direct ports vs. the ones with a less direct and seemingly more restrictive path. The Subaru engineers for some unfathomable reason, chose to place the exhaust ports close together so that the port arrangements for 2 cylinders are short and directly out whereas the other 2 have a very different design. Curious, to be sure and something that I don't think was the greatest idea on a modern engine design. I also pulled out my thick flow bench data book and looked up flow rates on 2 certified aircraft engines to continue to fuel the debate on auto vs. aircraft engines, which many of you have found quite interesting.

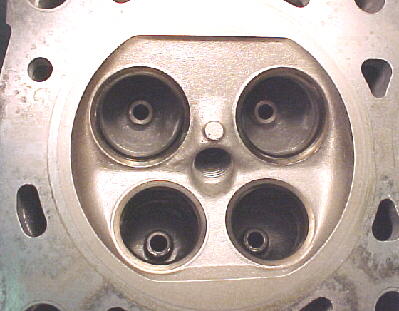

Before benching the heads, they were plastic bead plasted to remove all deposits. I polished some of the minor lumps out of the intake ports where the spark plug tubes meet the runners. I ported the very end of the exhaust ports out to 1 5/8 inches to match the ID of my header tubing. There is very little meat on these heads for porting purposes so be very careful in removing much material. Both the intake and exhaust ports looked well shaped for good flow. As stated before, the valve sizes in this engine are quite small at 31 and 28 mm for a 2.2 liter engine, no larger than many 1.6 liter engines, so I did not expect stellar flow rates. Peak valve lift is just over .300 with the factory camshaft.

A flow bench is a piece of test instrumentation used to measure airflow rates through cylinder heads or other parts. Air is flowed though the head at a fixed pressure and a dynamic/static probe attached to manometers allow airflow measurement. By improving airflow rates through the ports, increased hp can be made.

Airflow at peak valve lift on the intake ports was 114 SCFM at a test pressure of 10 inches H2O. On #4 exhaust with the contorted port, airflow was 81 SCFM and on #2 with the more direct exit, it was 83 SCFM. Airflow rates in the mid lift ranges were quite close to the Lycoming and Continental heads that I had flowed many years ago. The EJ22 ports were quite good stock for the valve sizes employed, however due to the lack of material available for reshaping, little useful improvement can be made to them. For an engine to be used in the 4000 to 5500 rpm range the ports are entirely adequate but this would not make an exceptional racing engine unless larger valves and better porting was employed. Compared to certified aircraft engines however, the EJ22 is in a different world as far as airflow rates and volumetric efficiency goes.

Fill ratio is a measure of the airflow vs. cylinder displacement of an engine and is directly relatable to volumetric efficiency and hp potential. The Lycoming O-540 with massive 2.2 and 1.77 inch valves, offers a fill ratio of only .092 and .067 respectively on the intake and exhaust ports. The Continental O-470 is little better at .103 and .067. The Subaru blows these engines away with ratios of .206 and .150. In other words, the Subaru inducts and exhausts air at over twice the rate per cc of cylinder displacement as these popular aircraft engines. Little wonder that the EJ22 stock produces 59 hp/ liter and the aircraft engines are around 34.

Fill rates on performance prepared stock block based auto engines can exceed .300 and .200 on 2 valve engines and .350 and .250 on 4 valve engines in many cases so the EJ22 is far from being top of the league in this respect. The shallow pent roof combustion chamber with centrally located spark plug is ideal for high thermal efficiency. Just comparing the port and valve shapes of the aircraft engines vs. the EJ22 points to how far things have come in 40 years. The Lyc and Cont ports and valves are truly a joke with seemingly no engineering in the modern sense having been applied here. This is born out by the flow bench results.