I am building a 4 place KIS Cruiser with a Subaru SVX/EG33 engine and Ross PSRU here in Johannesburg, South Africa. I started construction in December 1996 and at the time of writing this (July 2000) I am about 6 weeks away from the first flight, having just completed the painstaking task of painting.

The Subaru EG33 engine installation, including the manufacturing of a new custom cowling took exactly a year and so far it looks like it was worth it - I should know for sure in a few weeks. I made this choice of engine for a number of reasons, firstly, the cost of aircraft engines, both in initial purchase cost and in maintenance is prohibatively high (for me anyway), furthermore, the technology is 40 or 50 years old. Secondly, the Subaru range of engines have an extremely good reputation in aircraft circles. Unlike aircraft engine manufacturers, automotive manufacturers have made incredible advances in technology and I personally have an enormous amount of faith in auto engines, especially considering how most of them just go on and on and on, often regardless of their condition.

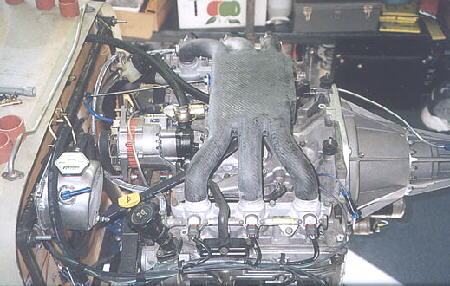

The EG33 in particular is an enormously strong and understressed, normally aspirated, fuel injected, 230HP, horizontally opposed 6 cylinder motor, which can stand up to the rigours of aircraft use superbly. After having gone through the whole process of getting an engine mount designed, making the mount and finally mounting the motor to the front of the airframe, the time had come to remove all the "junk" from the motor which would serve absolutely no purpose in aircraft use - like, EGR valves and tubing, bypass air control valves, air conditioner brackets, timing belt covers, etc. I even went so far as to attack the throttle body with a saw and grinder and removed 2 lbs of dead weight.

Probably the biggest and most difficult modification I made was to discard the stock intake manifold and make and install a new lower profile and lighter Carbon manifold. This proved to be quite a complex task, but the end result was definitely worth it. I also had new, lighter and simpler stainless steel exhaust stacks made. Another change was to replace the stock alternator with a lighter and smaller Mazda alternator/vacuum pump combination. A vacuum pump is required to operate the gyro instruments and as can be expected, the standard aircraft pump is ridiculously overpriced and also difficult to install onto the Subaru (aircraft motors have a specific port on the crankcase into which the aircraft style pump fits). This alternator/pump combination is found on most diesel trucks where they use the pump (which is mounted directly to the back of the alternator) to generate a vacuum which assists with braking, amongst other things. The only drawback with using this pump is that it requires an oil feed, whereas the aircraft pump is a dry pump. This wasn't too difficult to solve and I was very happy to see that once the engine was running, this pump drew more than enough vacuum to drive the gyros. I also added a Kawasaki motorcycle oil cooler in line with the oil feed to the Ross PSRU.

Another major step in the installation was to find and install a suitable radiator. I eventually found someone locally who built me the smallest custom aluminum radiator that I felt would work - of course, time would tell if this was in fact the correct size for this engine. So far I felt that I had succeeded in my intention, which was to simplify and lighten the engine as much as possible - because in its stock form, the EG33 is quite a heavy and bulky motor. Of course, I will only know whether I was successful or not once the weight and balance calculations on the entire aircraft have been done.

Another major change was to discard the stock EFI controller and replace it with a simpler and more suitable dual redundant, fully programmable EFI which had been specifically designed for aircraft use. I chose the FuelnFire - manufactured by Compass Avionics as I felt that it would give the flexibility, redundancy and the simplicity I was looking for. The only difficult part to this installation was the design and manufacture of a mounting arrangement for the dual cam position sensor PC board as well as a mounting plate for the trigger magnets.

I was able to make use of the stock fuel gallery and side feed injectors that the Subaru uses as well as the stock coils - the EG33 uses 1 coil per cylinder and these are bolted directly onto the back of the plugs, thus doing away with any traditional spark plug leads. The only other inputs the EFI required, were power, ground, air temp sensor, cam position sensor, water temp sensor and throttle position sensor. All the programming was done using a laptop PC, a mixture meter and lots of trial and error. Eventually, after a fair amount of problem solving (most of which were caused by mistakes in my wiring), I got the motor working and was immediately impressed with how smooth it ran. At this time, all that is required is to fine tune the motor and solve a cold starting problem and then I'll be ready for the first flight.............hold thumbs!!!

John Petrie

09/14/00 John recently made his first flight. Unfortunately the flight was curtailed due to serious overheating. A re-design of the cooling system is underway now.

Update 12/03/00

Hi everyone, this is probably the most difficult e-mail I've had to write for a long time, but I just can't wait any longer. As you all know, I have recently been raving about how well my EG33 is performing and how finally all the problems have been sorted out. Well, that still applies.....sort of........the EG33 is still perfect, as is the Ross PSRU and the engine mount, However, the rest of the project, my KIS Cruiser is very badly damaged.

On Wednesday morning, the test pilot and I took the plane up for it's 4th test flight. Everything ran absolutely perfectly for about 20 mins and then suddenly there was silence. We had some sort of electrical failure that caused the engine to shut down completely. We are still investigating the cause, so I can't elaborate much on why the power failure happened. Anyway, the result was that we attempted a forced landing at the airfield and due to a variety of reasons we weren't able to make the runway - instead, we crashed about 30 metres before the threshold doing 85 mph.

Most of the impact was absorbed by the nose gear and then the main landing gear (a good reason not to fly a tail dragger:)) Both of these broke off the plane immediately and we skidded about another 60 metres down the runway before coming to a grinding halt....literally! Fortunately, both of us were able to walk away from the accident totally unhurt - a huge testament to the strength of the KIS Cruiser.

I'm not going to go into great detail here, but the essence of this story is to say that I have finally completed my engine experimentation and (with some pressure from the family I might add) have decided to rebuild the plane and install an aircraft engine. As a result, I am looking to sell the EG33/Ross PSRU plus a whole bunch of extras - far too numerous to mention here, to anyone who is looking for a really fantastic engine with only 15 hours on it. I am happy to be more descriptive about the package to any serious buyers. The asking price is $8500US. I must also stress that the engine was totally unscathed in the crash and the wooden Prince prop, which was windmilling at the time, was destroyed, so I would therefore recommend that the future owner has the PSRU checked before using it again. Thanks to everyone who sent such kind words about the success I was having with the project, and to the person who asked if I was going to miss building...I guess not!

John Petrie

E-mail Racetech if you are seriously interested in the EG33 engine package.

We're all glad that John and his friend survived this incident without injuries. We can learn something from this accident. Again, it was not mechanical engine failure which caused this, it was a system failure. I cannot stress enough how important system design and installation is to total reliability. Any EFI equipped engine using electric fuel pumps can fall victim to electrical failure. Simple problems such as bad grounds, connections, routing, chafing or breaker problems anywhere in the system can bring you down. Treat these with considerable care in the design and execution stages.

R. F.