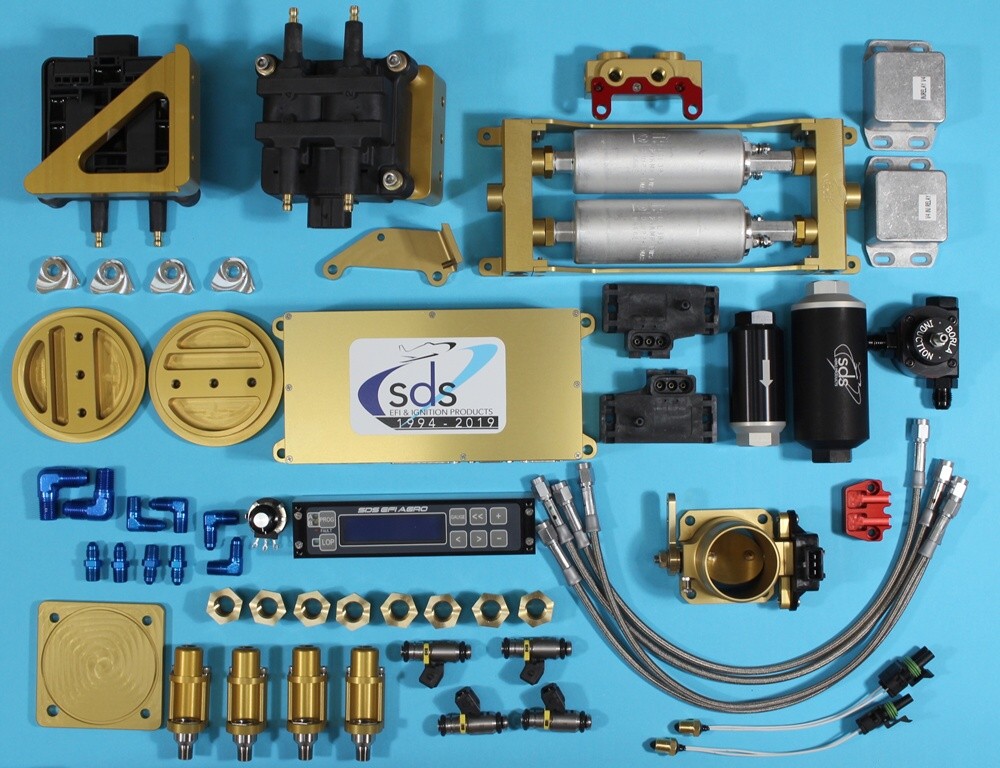

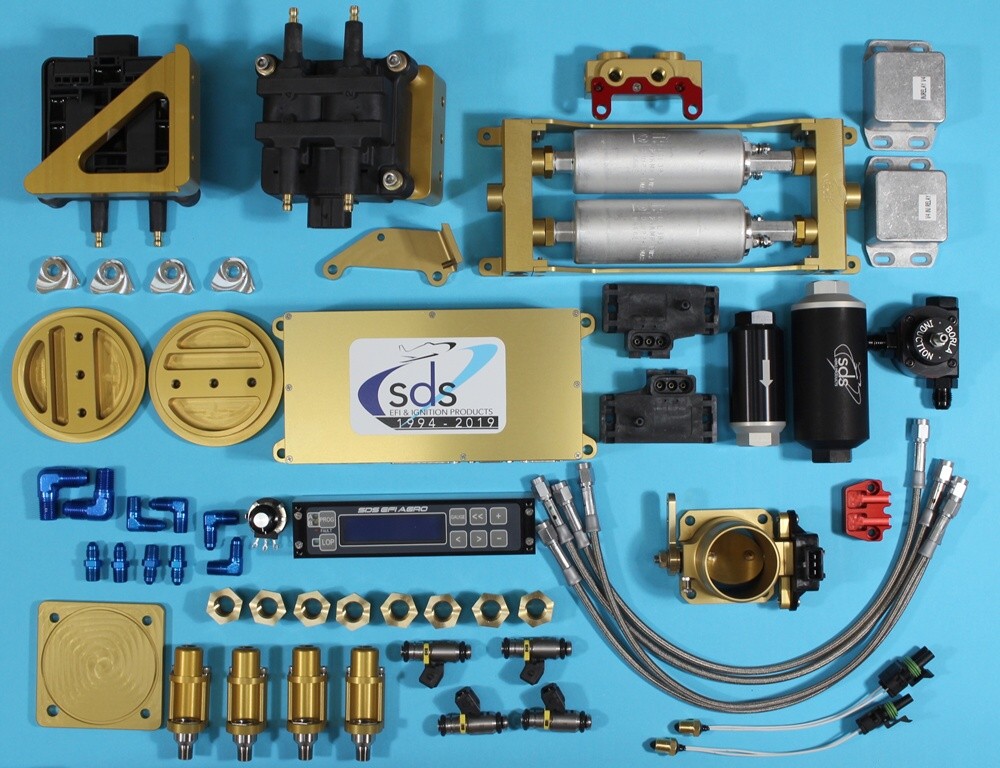

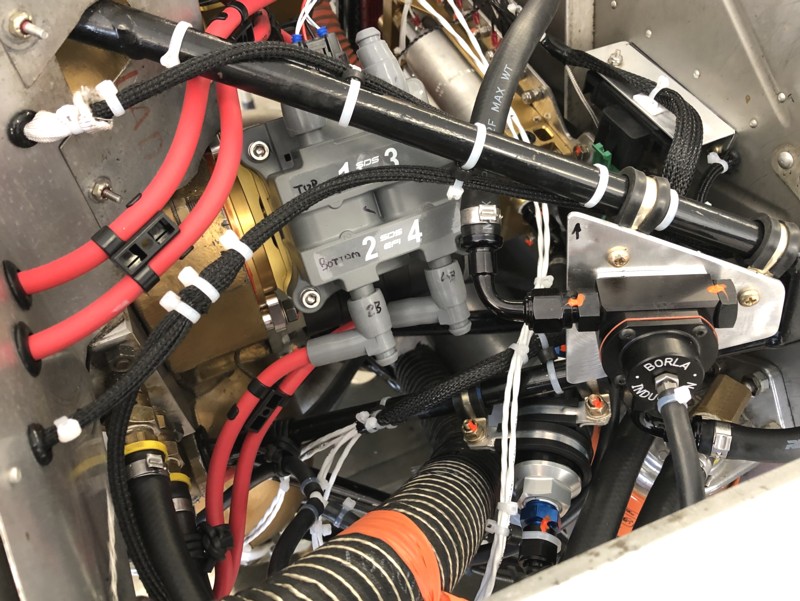

Fuel and spark control kit for O-200. Wiring harnesses, fasteners and plug wires not shown.

Phone 403-671-4015

E-mail:racetech1@telus.net

Last update June 23/25

We have done a number of smaller Conti engines, the first back in 1996. Mark Snow was an early SDS user on his C-85 powered Dragonfly, accumulating over 750 hours. Justin Mace had 350 hours on his SDS equipped, O-200 powered Dragonfly.

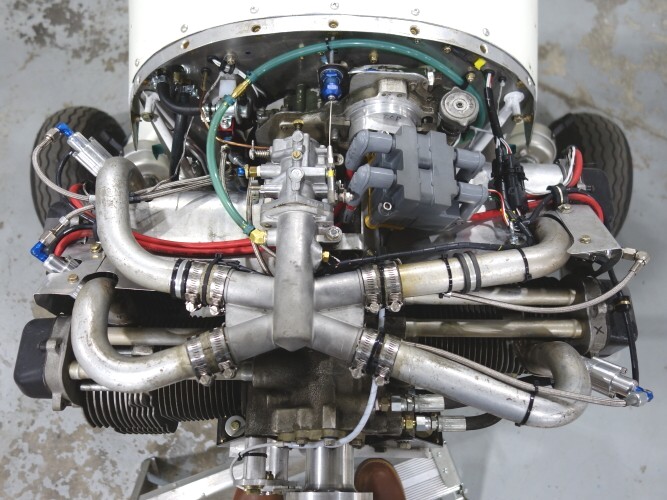

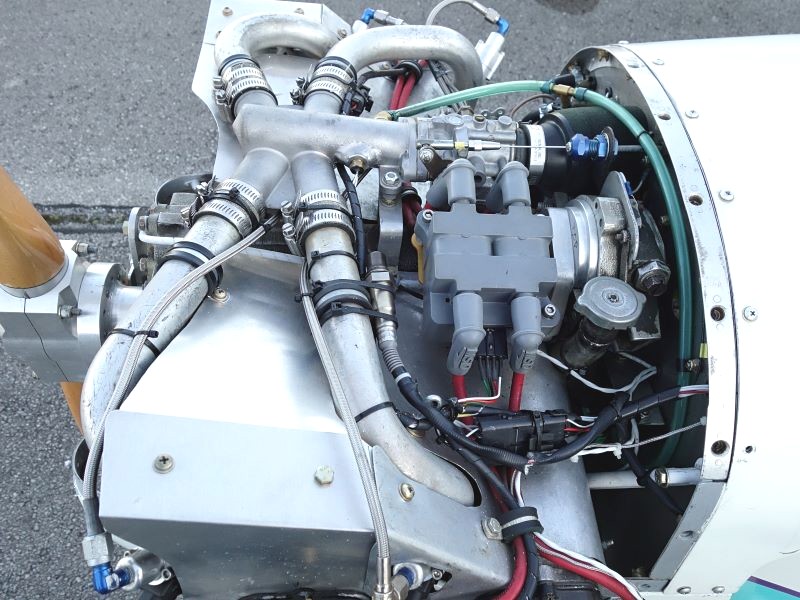

Fuel and spark control kit for O-200. Wiring harnesses, fasteners and plug wires not shown.

Options: fuel trim $300, card data logging $240, Digital fuel flow $100

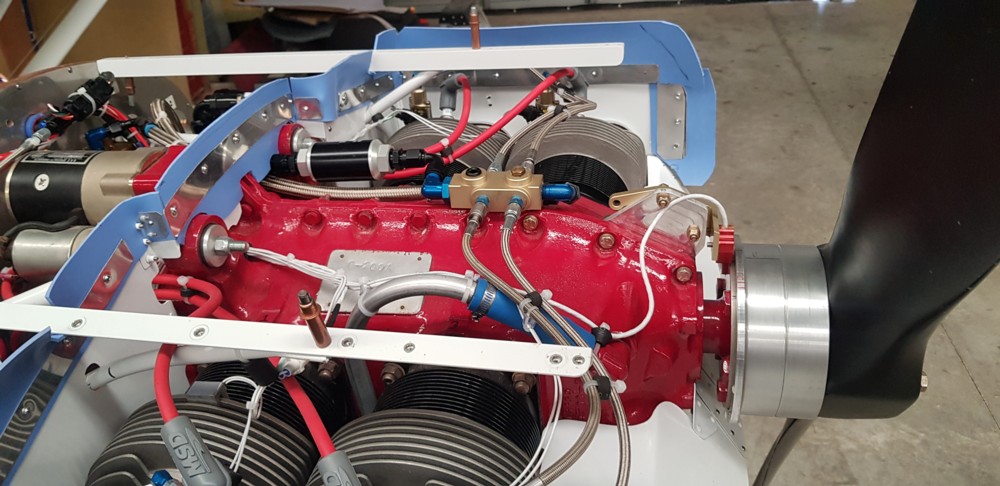

SDS on O-200 by Malcolm Savill in NZ

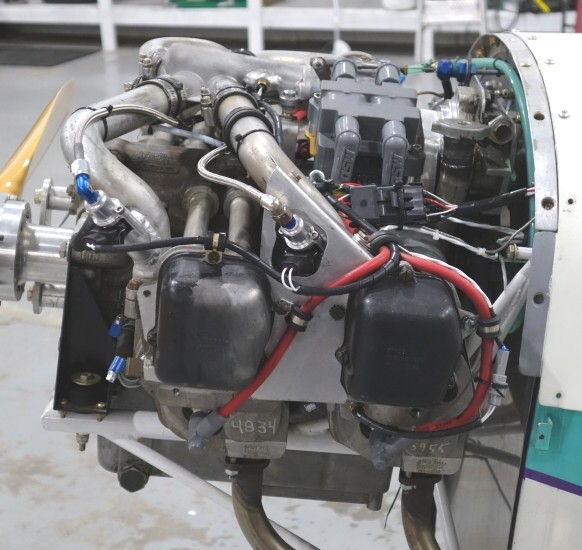

Bert Caron did an SDS EFI installation on an O-200. With some fin mods, he was able to fit the Lycoming style injector bosses into the Continental heads.

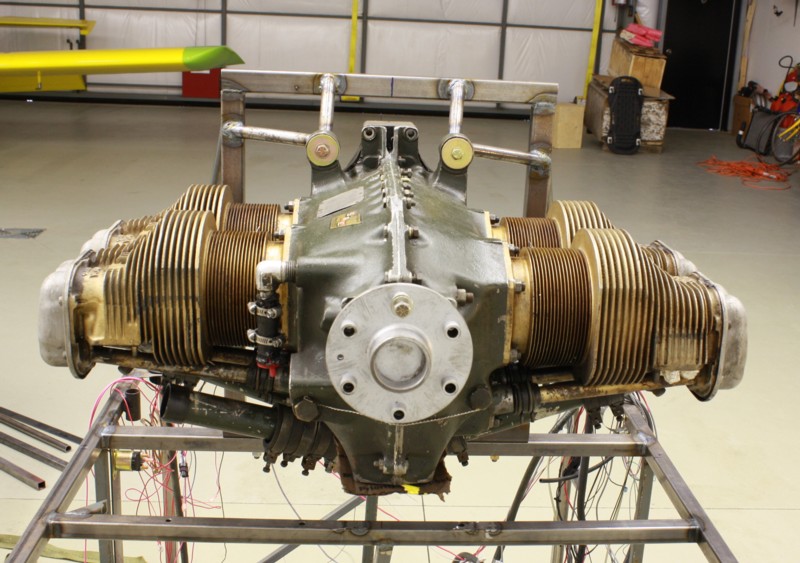

Mar. 15/17. We acquired an O-200 for jigging and development purposes. This was used to design some new CNC'd parts to make the installation easier on these engines which resulted in our new EFI kit shown above.

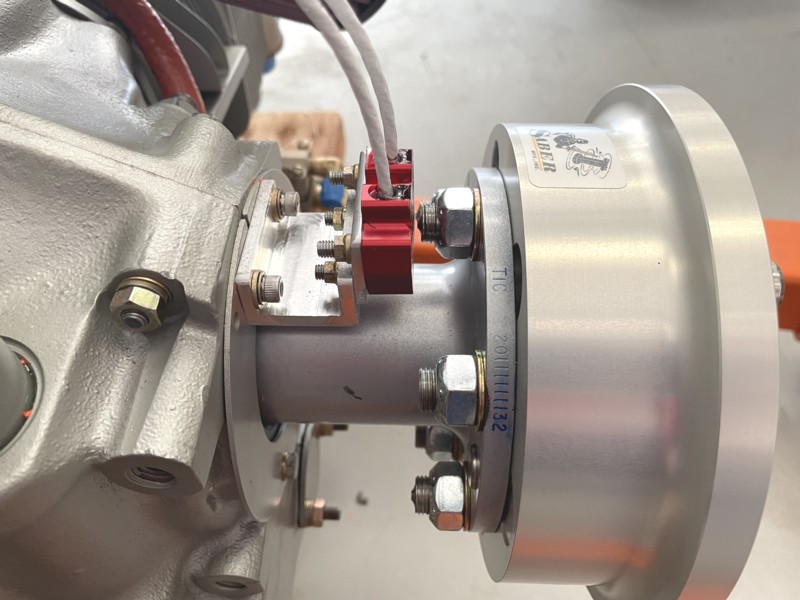

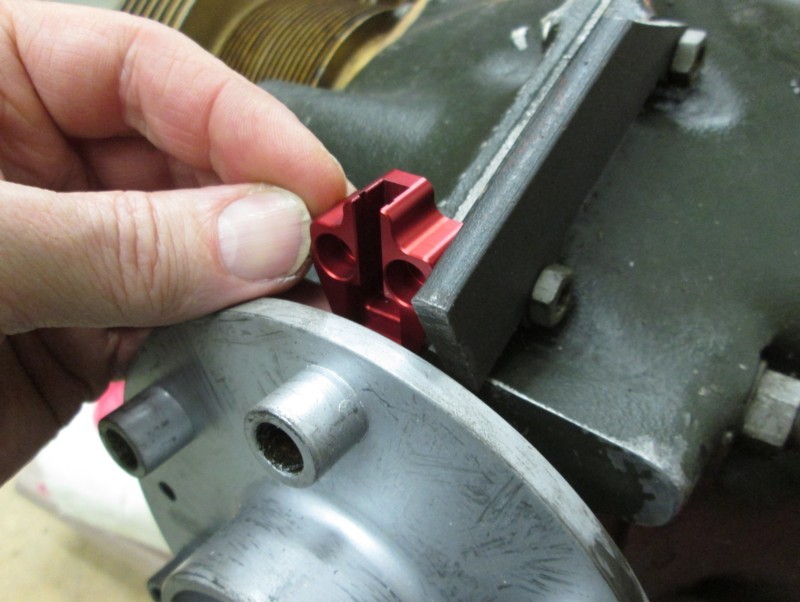

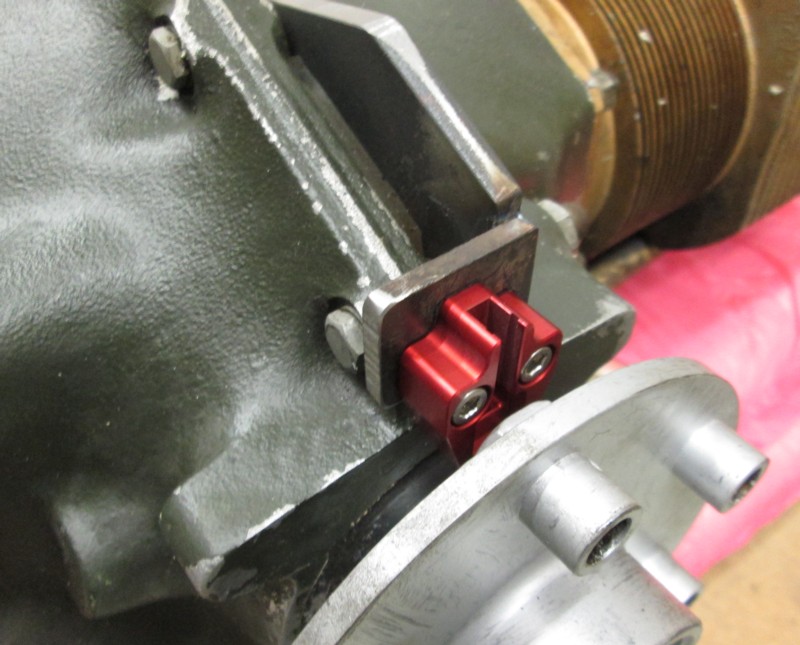

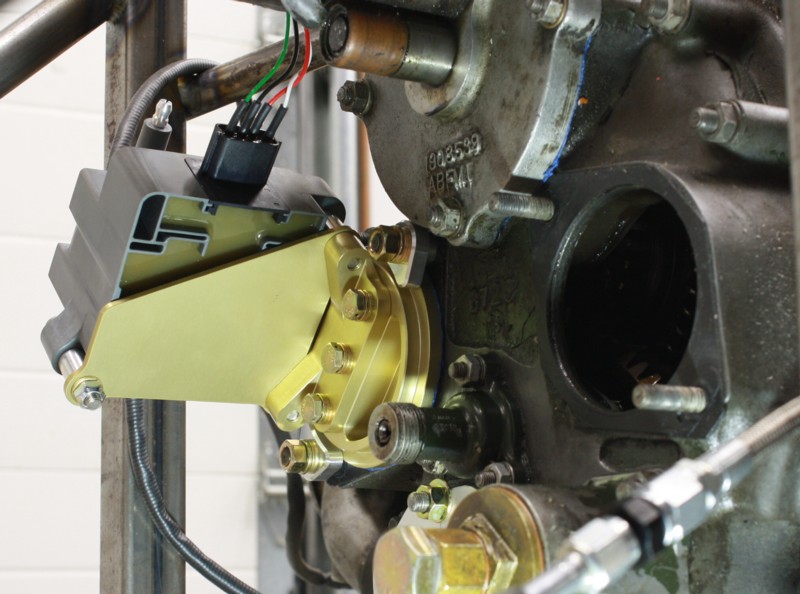

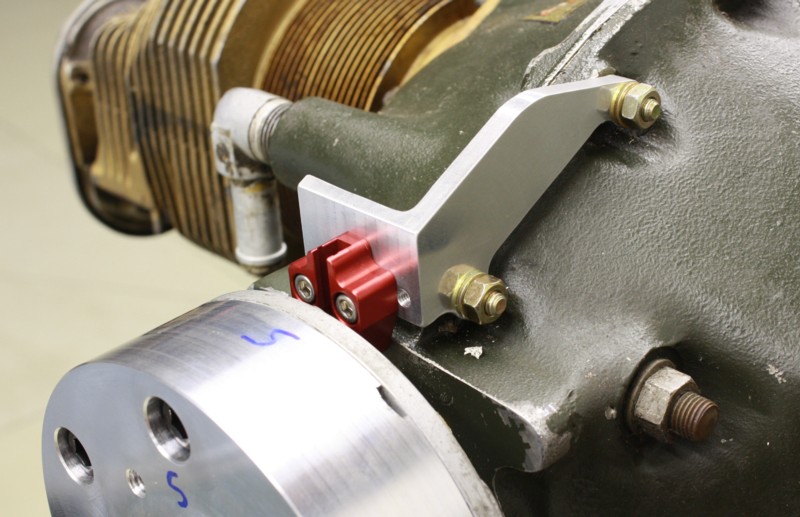

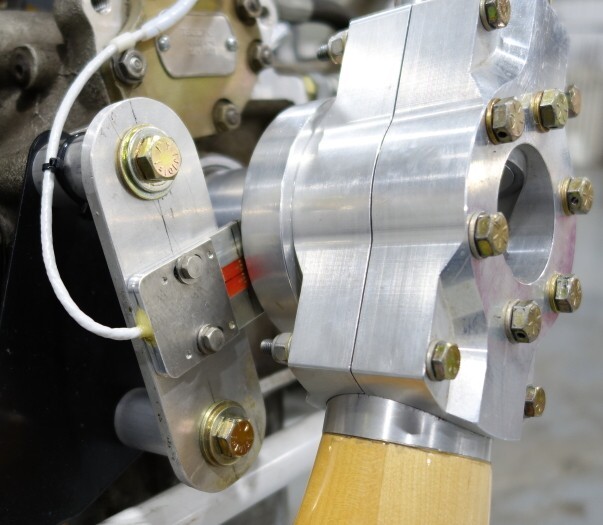

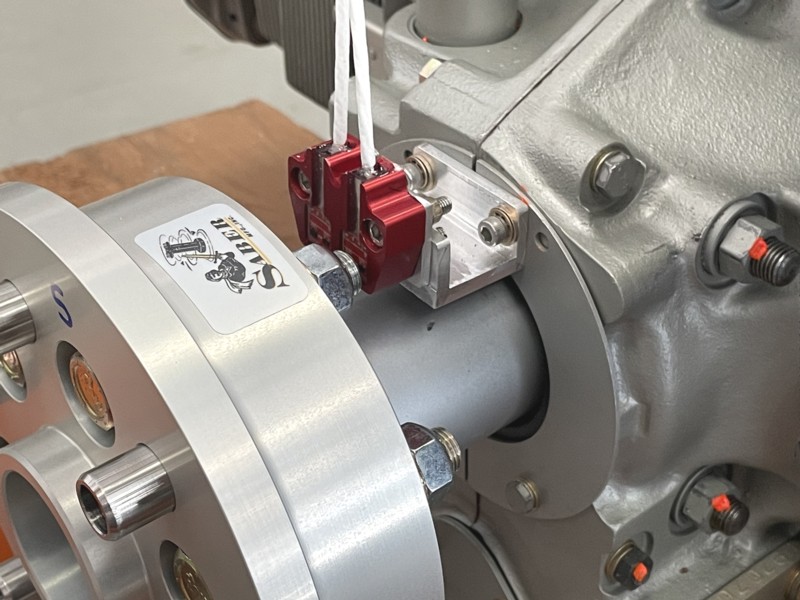

Working on prototype Hall sensor mount

Machined up some engine mount hardware to mount the engine on the test stand

Prototype Hall sensor mount fabbed up

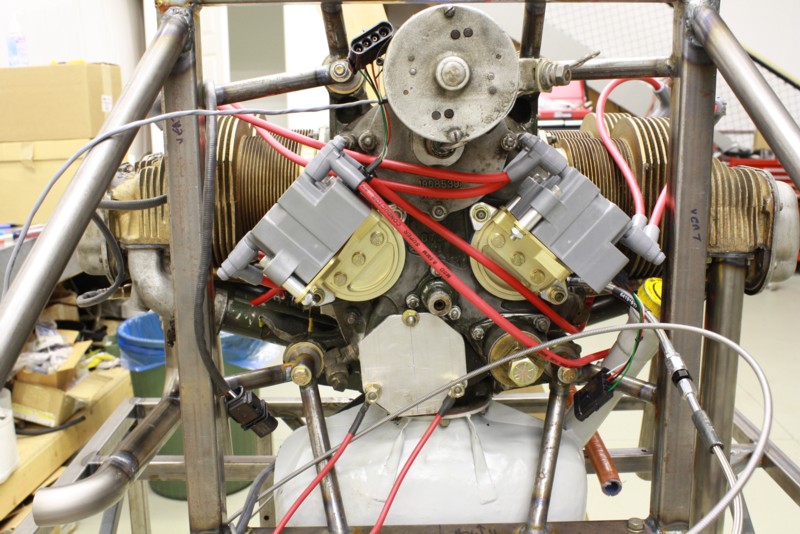

Coils mounted in old mag position

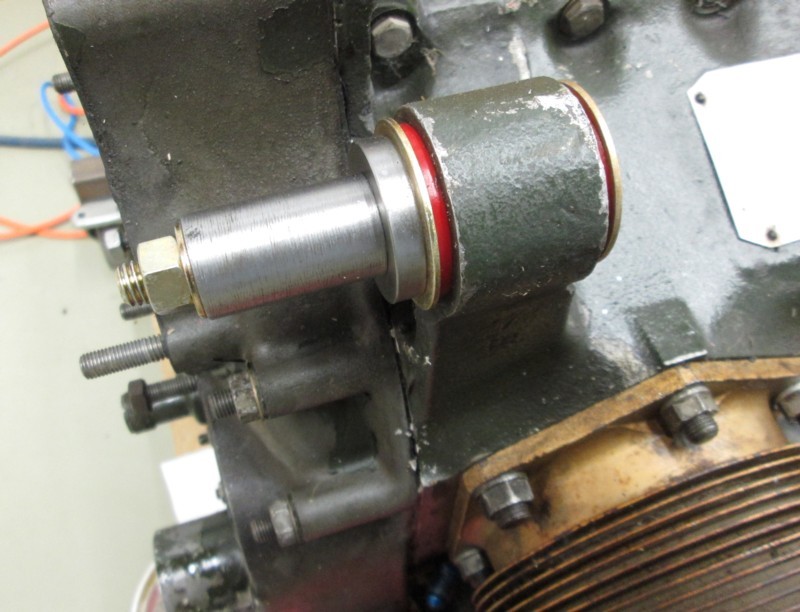

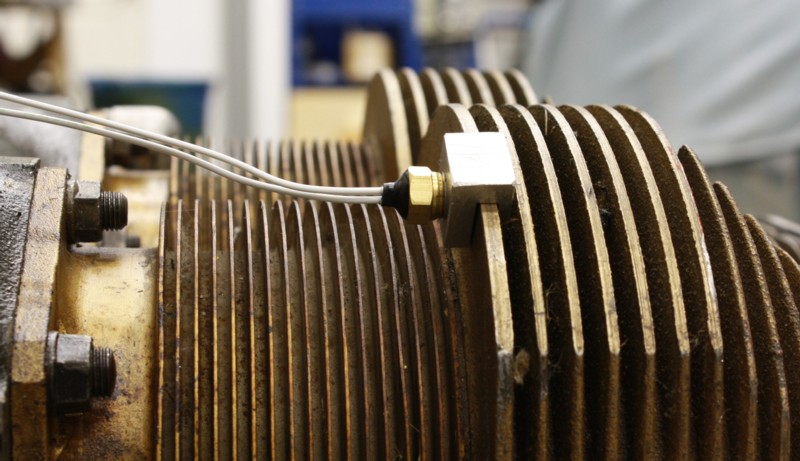

CHT sensor mount for starting and warmup

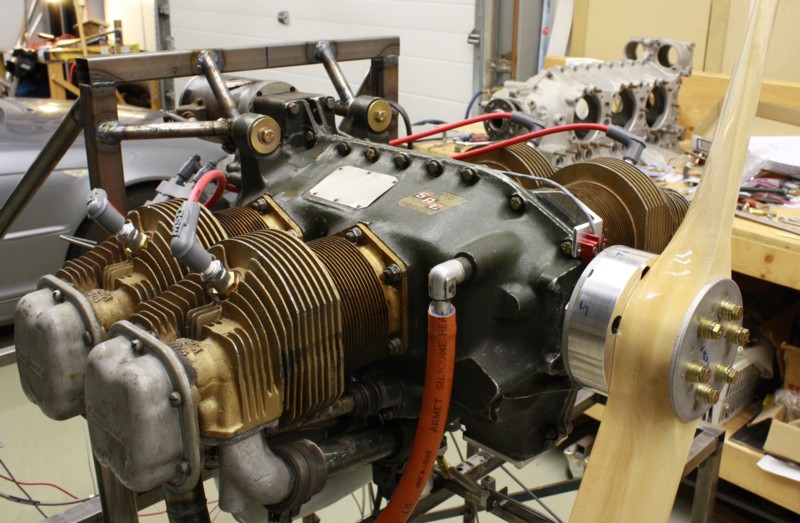

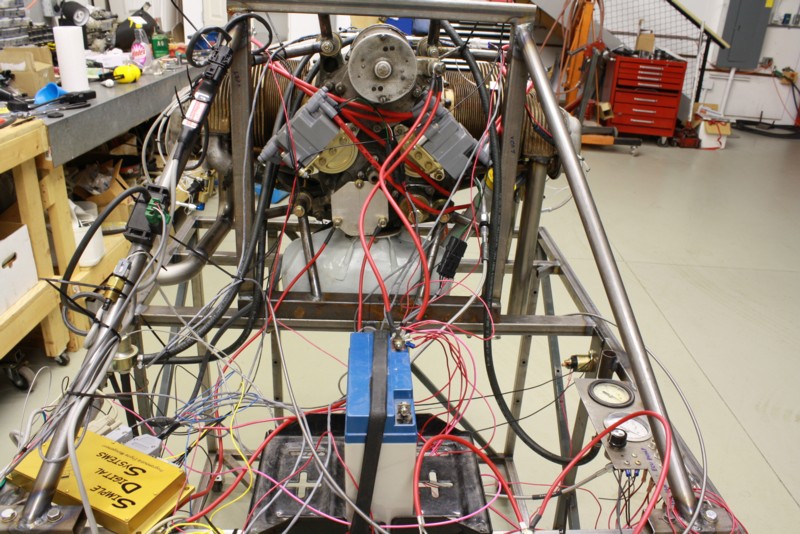

Engine mounted up on test stand

Engine with sump, plugs, fuel pump, starter installed and engine stand support arms fabbed. BMW is used for dead weight to keep the assembly from running away.

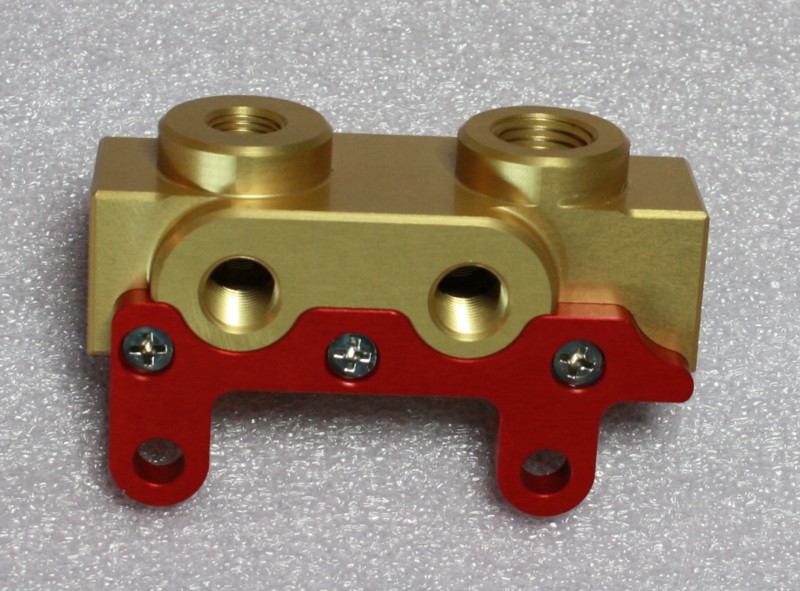

New CNC'd bits

Coil pack mounted up to left mag position

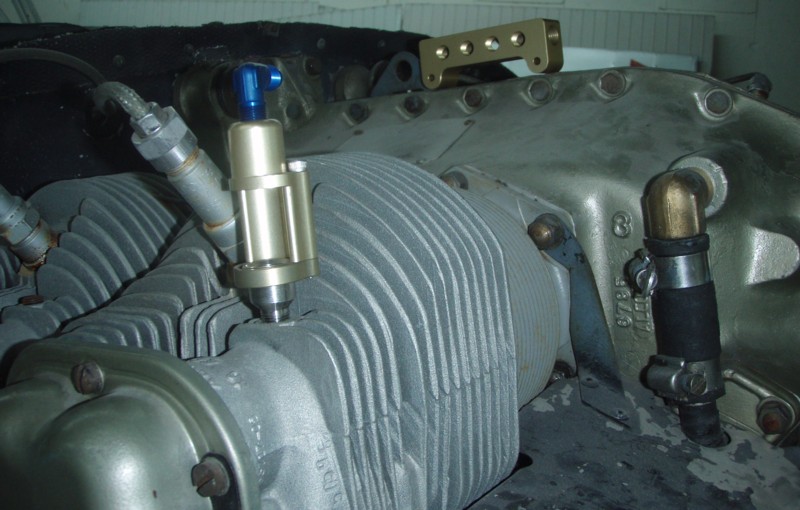

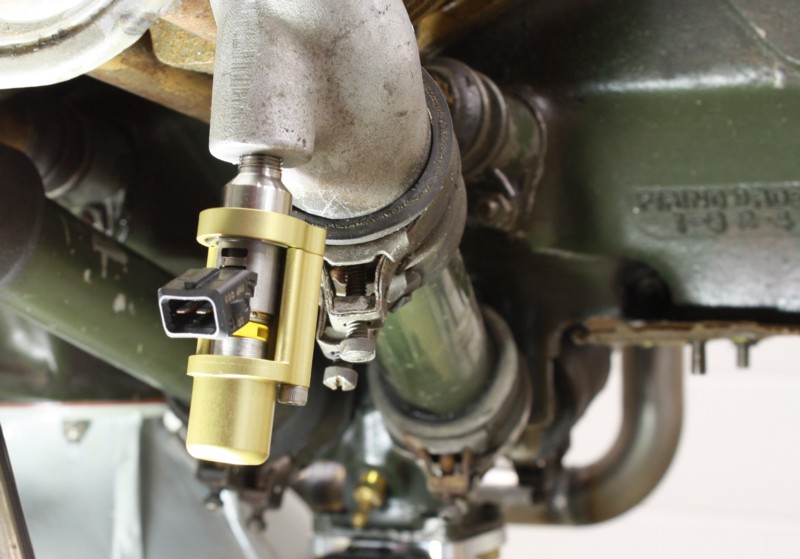

Injector mounted to induction elbow

Throttle body in place

Hall sensor bracket

Plug wires and throttle linkage installed

Both coil packs installed with plug wires

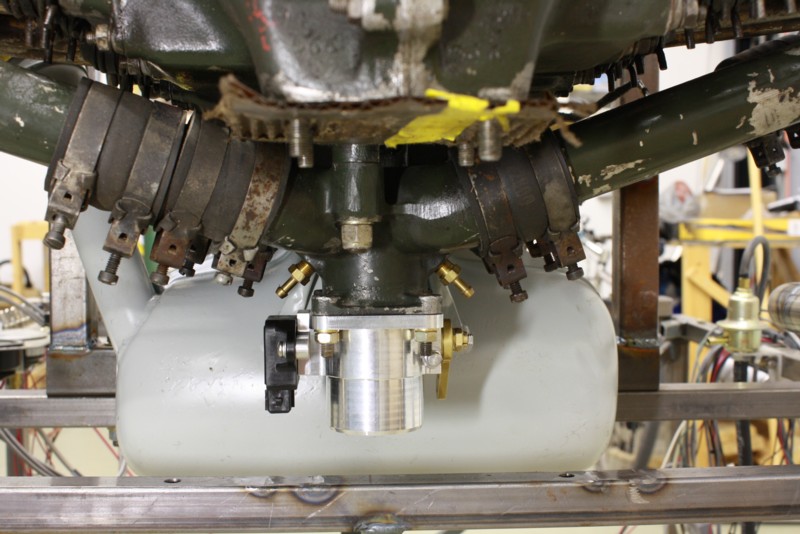

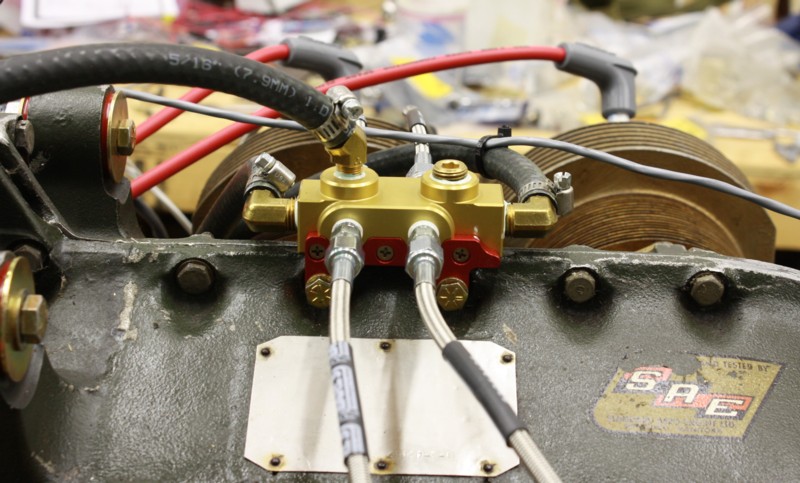

Fuel block for O-200

Engine all hooked up on test stand

Fuel block

Rear view

Injector detail

First run

750rpm idle

Running video: https://www.youtube.com/watch?v=gmGnvOa9RsE

Startup and running to 1800 rpm.https://vimeo.com/221821595

WOT testing to 2400 rpmhttps://vimeo.com/223383470

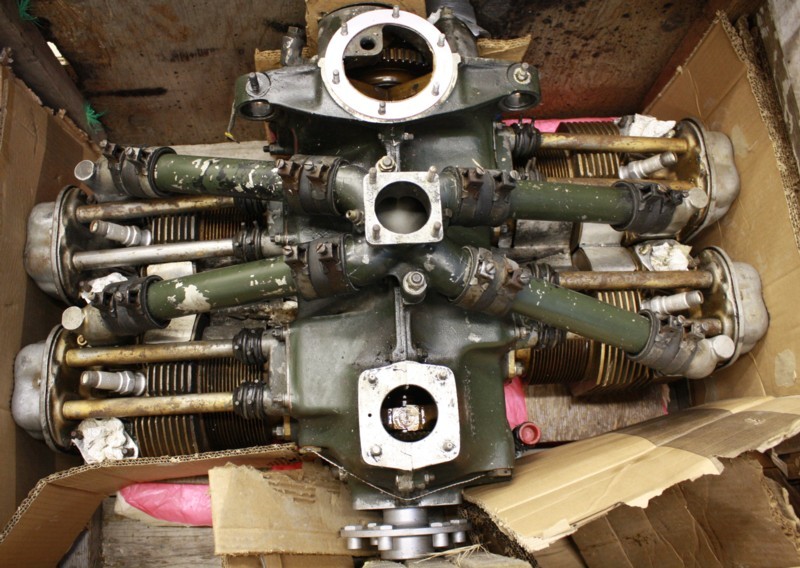

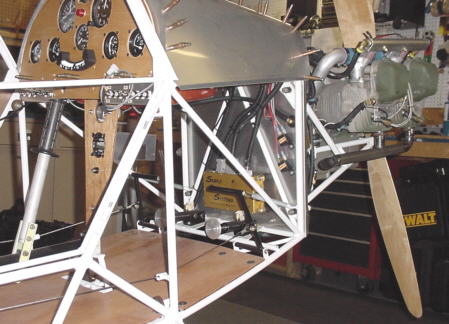

Les Smoot's J-3 Kitten powered by 84 cubic inch 4A084 GPU engine fitted with EM-4 4D fuel injection system

Jim Jernigan's SDS Installation on his 4A084 powered SkyRaider 1

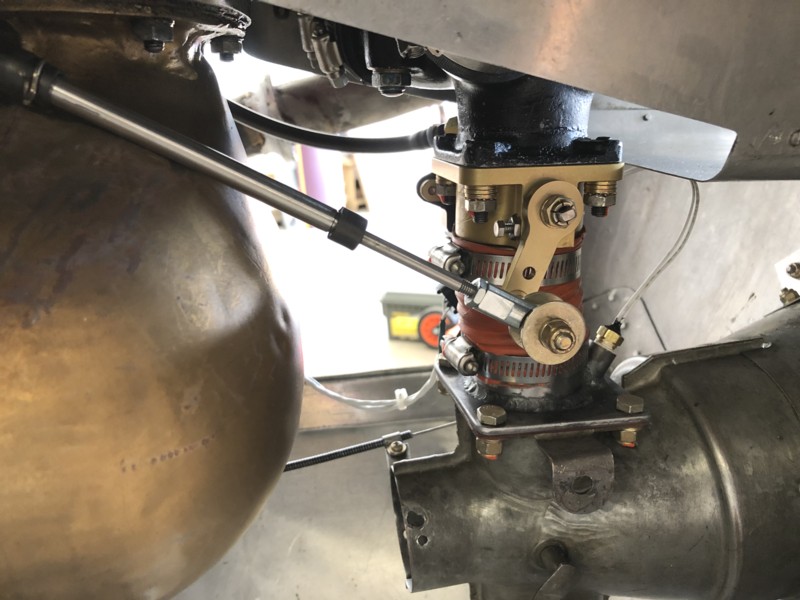

Crank sensor mount detail

Some of Jim's comments:

"The results were: easy starting, winter and summer, smooth, slow idle, 20% gain in maximum static thrust and consistent, rock solid performance in every aspect of engine operation. These were previously unattainable with my stock, icing prone carburetor and magneto."

Dual Hall sensor mount detail on Conti O-240 (Dave Magaw)