This car was owned by Racetech Inc. and used for product development/testing. This article details the installation, tuning and testing of an SDS EM-4 6F system. The car was essentially stock other than having a Supersprint exhaust system already. We installed new brake rotors, Metal Master pads and Koni/KYB shocks front and rear with the lowering already done to the suspension.

Stock Motronic installation

Before removing the stock Motronic EFI system, we carried out some acceleration tests to baseline stock hp levels and tested afterwards with SDS fitted:

0-60 mph 8.2 seconds, with SDS 7.5 seconds

3000-6000 rpm 2nd gear 4.3 seconds, with SDS 3.8 seconds

3000-6000 rpm 3rd gear 11.0 seconds, with SDS 9.6 seconds

1000 rpm rolling start to 100km/hr 9.3 seconds, with SDS 8.0 seconds

Tests carried out at 0C and 3500 foot elevation. Car would be about 10% quicker at sea level.

The stock airflow meter was very small measuring only 1.75 x 2 inches on flap door. This had slightly less area than the 60mm throttle body butterfly and appeared highly restrictive. This proved correct after mounting various components on our flow bench. With the bench flowing 161SCFM, the TB showed a drop of 2 inches of water. With the inlet elbow hose on the TB, drop was 2.5 inches. With AFM on, flap wired fully open, 5 inches drop. With the BMW velocity stack installed and the airbox, 5.5 inches drop. There was little change removing the stack as it was judged to be too close to the airbox wall to be useful. With the AFM flap not wired open, restriction was 8 inches. The AFM would be replaced with a 2.75 inch tube attached to the modified factory airbox and K&N filter.

Stock airbox with velocity stack

Stock AFM flap detail

Throttle body with SDS TPS mounted on custom machined adapter

TB on flow bench

The airbox was ported to accept the larger, round tube in place of the AFM. A flange was fabricated and TIG welded to the tube. A Bosch air temp sensor was mounted in the airbox.

Airbox opening ported to match new tube. Note new Bosch air temp sensor.

The stock Motronic system used a magnetic sensor and a multi-toothed timing disc mounted behind the crank pulleys for ignition triggering. The stock setup was replaced with the SDS Hall effect sensor mounted to a custom bracket off the oil pan flange and the 4 high performance magnets mounted into the stock timing disc.

Hall mount and installation on engine

Looking up and sensor and mount

After much struggling with German engineering, we removed the pulleys and timing disc to install the magnets. We changed the timing belt and tensioner at the same time. Below details the marking and mounting of the magnets for the 6F system.

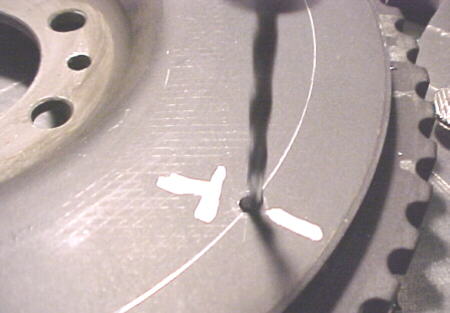

A mark was put on the disc where the hall sensor was, crank at TDC #1. Disc marked with arrow for direction of rotation.

Crank set at TDC #1

Circle scribed on disc on lathe. Note mark for Hall sensor.

Paper protractor lined up with Hall sensor position mark in direction of rotation indicated by arrow. Mark along circle where this intersects is where A trigger magnet is placed.

40 degree protractor is placed next to this mark. Indicates where synch magnet will be mounted

Shows both protractors for clarity

Punch marking A trigger and synch positions respectively

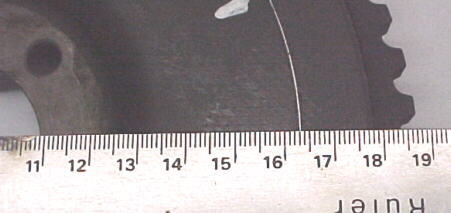

Diameter of circle measured with calipers or precision ruler as shown

Using the formulae in the manuals, B and C trigger magnet positions are calculated and marked using calipers. Magnet A lower right, B straight up, C lower left, 120 degrees apart.

Drilling .125 inch holes. Check depth frequently. Want 1 to 1.5mm protruding above disc face on ferrous materials. Can be flush or above on aluminum pulleys. Magnets cemented in place with 5 minute epoxy.

The factory injectors are marginal even on the stock engine, being only 145cc/min. These were replaced with Bosch 300cc high impedance injectors.

Bosch 300cc injectors

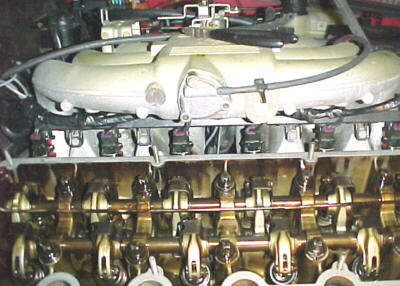

The valve cover was removed to allow access to the fuel rail for removal. The fuel lines from the fuel pressure regulator were changed at this time as they were cracked.

New injectors installed in rail

Shot of engine with SDS installed

SDS ECU mounted in glovebox

We retained the factory crank sensor, wiring and ECU to run the tachometer as it could not be made to work with the 6F coil pack. We were not impressed with the quality of the rubber and plastic parts on the BMW after working on Japanese cars mostly. For a 12 year old car, many were cracked or broken. The wiring is a nightmare and illogical so this is not a project for the faint of heart. This was the most complicated and time consuming SDS installation that we have done.

11/27/02

The car is now running and we will have mapping and performance figures and other updates in the near future. For now, throttle response is noticeably quicker with the airflow flap gone. Cold start, warmup and top end power are all better with SDS than the Motronic. There have been no issues with interference or RPM error codes despite the close proximity of the Hall sensor and main wiring harness cables to the 6F coil pack and ignition wires. We did this on purpose to simulate the worst possible EMI/RFI environment.

12/16/02

With over 7000km on the car now with SDS, we are happy with the running of the car. The engine has the same flat spot in the torque curve as stock between about 2000 and 3500 rpm, possibly due to the intake manifold design. This is not a torquey engine. It responds well to being revved high if you need to go fast. Luckily, it pulls well and smoothly from 4000 to the 6500 rpm redline and sounds great. We have the engine running in closed loop under cruise conditions and this seems to work well. Mileage in city use is 24 Imperial, highway 29mpg.

06/04/03

We have about 9000 km. on the car now. We ran the car recently at a BMW drivers school so the engine saw lots of hard laps with many shifts off the rev limiter. Engine and chassis worked well getting about 175km/hr. at the end of Race city's straight. The new tires and wheels made a world of difference in handling and grip.

04/17/06

This car has been sold now and had 56,000 km on the SDS unit to date.