This car was purchased to become a daily test vehicle for SDS in four seasons and also for Solo 1 events. Our goal is to produce about 220 HP reliably. Sorry, if you would like to read about 600HP Imprezas, you will have to buy a magazine.

The Impreza was all stock with the standard NA 2.2 making about 130HP, which of course is not enough, so we decided to swap it out for an EJ22T Legacy Turbo engine. We first had a good look at both engines to see that engine accessories such as the power steering pump and A/C would bolt on. Factory exhuast manifolds fit in the chassis, but one part that would not bolt on was the factory up-pipe since it would not clear the crossmember. A custom up-pipe would need to be fabricated, since we did not have a Legacy crossmember. And since we picked a T3 turbo, there was no point in using the old up-pipe anyway. Engine management is by an EM-4 4F firing the factory coil pack. Turbo is a Garrett T3, -60 compressor, .63 Stage 3 turbine.

Hmmm, how much will we need to cut?

Later, Not too much really. An immediate bend at the flange helped minimize

cutting the crossmember.

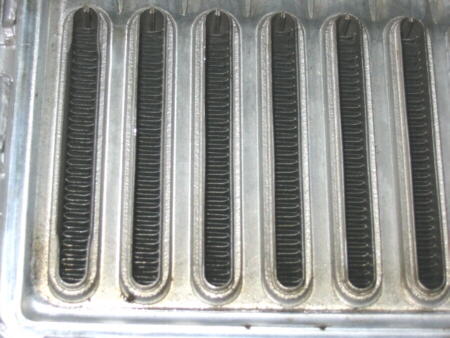

WRX intercooler was a good choice since it has internal fins, is quite

large, relatively cheap and easy to find on ebay.

Temperature rise is only around 10 deg C at 8 PSI.

End tank is easy to remove for modification. Just bend the crimps. It's

sealed by a rubber gasket. Reassembly is also easy.

Underside view of modified WRX interooler with original inlets capped

and new 2" inlet pipe welded onto the inlet tank. There would not have

been enough clearance to use the existing inlets in the 98 Impreza chassis.

Furthermore, building a Y pipe would have been very difficult and wiring

and A/C lines would have needed relocating. Two cover plates end up very

close to the brake lines on the firewall, so care must be taken to make

sure there is no contact. Custom supports were made using 1/2" square steel

tubing.

A cutsom fabricated hall sensor and bracket were used.

Magnets were placed in the flywheel.

Clutch:

Three bad things about the OEM clutch:

Cable operated.

Shudder problem when releasing the clutch.

Probably won't handle torque.

So we installed an Exedy 15801 clutch.

We found a pedal set and hydraulics through Lachute Subaru. A clutch

fork was still needed and we happened to have a '77(?) Celica transmission

in our shop. Well lucky for us this fork was perfect for the job. Length

and pivot pin locations were correct.We also had to use an adjustable push

rod on the slave cylinder.

If any of you out there are doing the hydraulic conversion it may be

wiser to pay the money and order a Legacy clutch fork form a dealer or

bone-yard. If you use a Celica fork we are not exactly sure which year

this fork was used. The fork is cast iron and we have noticed some model

years used a stamped steel fork which may or may not work.

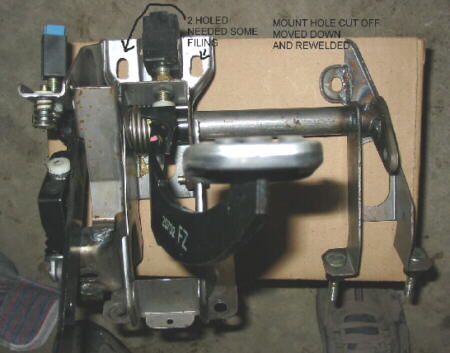

Pedals and hydraulics

WRX pedals See photo. This is not a simple bolt in. Some minor mods

needed!

PDM CSRK sleeve kit which will help protect the aluminum snout of the

transmission. This kit installed easily in minutes. From Mike Shaw Subaru

in Thornton, CO.

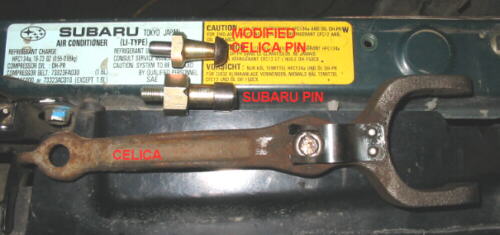

Pins and Celica fork.

Clutch pivot pins. Subaru on left and modified Toyota pin on the right. Toyota

pin had a larger thread which we cut down on the lathe and rethreaded.

The length of the toyota pin was perfect.

Clutch installed and celica fork installed. Looks good.

Pivot pin is in the upper location. The cable clutch setup used the

lower pivot pin location.

Up-pipe during the tack-weld stage. Engine was in and out of the chassis

several times while making sure parts would not interfere in the chassis.

1/8" thick schedule 40 weld elbows and pipe were TIG welded to build

the up-pipe. Heavy but strong.

Engine on stand. Building heat shield. Up-pipe also has an upper support

that bolts onto the cylinder head.

Up-pipe. Sorry, we cannot build these for people

We only built one. Please don't ask!

Air horn was made with 2-1/2" pipe made to fit OEM air filter box.We

used silicone hose couplers supplied by PTR Injection in Spokane WA.

We used the '98 intake manifold since it allowed more clearance between

the firewall and the throttle body. The Legacy intake would not have worked.

We used the Legacy Turbo 36Lb/hr injectors in the '98 fuel rails. Fuel pump

and fuel pressure regulator are stock '98. Engine has worked well so far

up to 10 PSI of boost and 6000 rpm. These engines seem to blow a lot of

oil out of the breathers when driven hard on the road course, and I had

to build a catch tank which holds about 1/2 quart of oil and it's still

not big enough. Will have to isolate which breather is tossing out the

oil and maybe rework the breather hoses.

Will attempt to run 12 PSI soon. Thanks to Ross, Duncan and Jim for

their help with this project.

See the progammed values for this car

Completed installation.