Please note: As of Sept. 17/25, direct mail shipments under $800 to the USA are subject to 35% tariffs. We are presently working with a broker in Montana to facilitate tariff free clearance under USMCA agreements. Most shipments will go via USPS and they charge 2% of invoice value to clear and process shipments. We are not able to ship by Fedex any more. Some non USMCA kit components will be deleted from kits to avoid high tariffs and we'll provide part numbers and sources for you to order these parts from the US. The tariffs have created big delays in getting kits done and shipped due to the massive amount of paperwork required now. Lower value shipments will be sent directly by mail and we have to charge the 35% tariff up front. Sorry, we cannot expend the time to file the USMCA paperwork on these items.

We supports jobs, industry and the economy in North America- 70% parts

content from US suppliers.

Last Update: Jan. 21/26

Payment is usually by Visa, MC or wire for US and international customers, E-transfer for Canadian customers. Please note: due to the uncertain status of proposed tariffs by the US on Canadian goods, we've removed pricing information on our site. It's usually best to contact us by email or phone. We can discuss your needs and quote a price for your order.

Phone 403-671-4015

E-mail:racetech7@proton.me

Due to the vast size of this site, it's sometimes hard to find what you want so here are some tips and links for aircraft specific things:

Search tip- Use the CONTROL F command to help locate certain words on that page.

We currently offer 3 basic electronic products for Experimental aviation:

1. CPI. This is a low cost, lightweight, user programmable ignition-only product intended to replace magnetos and other legacy EIs on Lycoming, Continental, Rotax and Jabiru engines. More info here: CPI

2. CPI-2. This is a user programmable ignition-only product with smaller, panel mount display and remote mounted controller intended to replace magnetos and other legacy EIs on Lycoming, Continental, Rotax and Jabiru engines. It's an evolution of the original CPI with more features added like automatic backup battery switchover, OV protection, display dimming etc. More info here: CPI-2

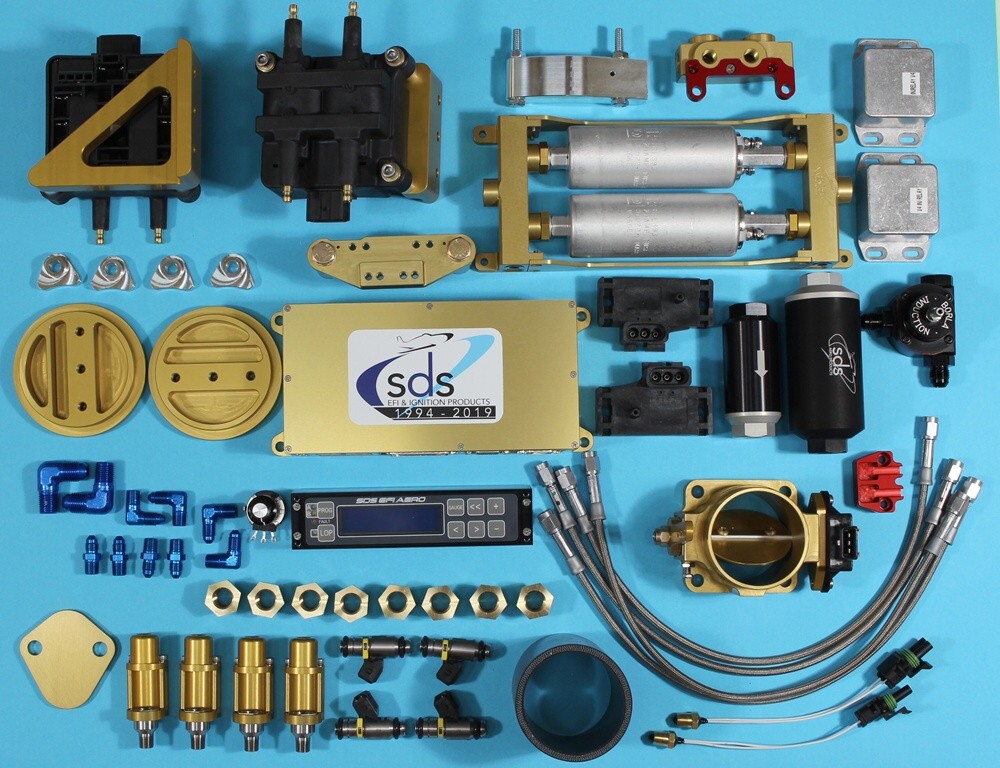

3. EM-6. This is a user programmable electronic fuel injection controller or EFI plus integrated electronic ignition. Kits are available for popular aircraft engines to replace legacy carbs/ mechanical fuel injection systems and magnetos. Available in many different configurations in either single or dual redundant ECU setups. See the photo below for a typical example of the EM-6.

Basic components of dual EM-6 4F EFI aviation system for Lycoming 4

cylinder engines. No wiring shown here.

We believe this is more programmable ECUs than all other brands combined

in the Experimental market.

Latest SB June 16/25 Starting Circuit Diodes

We also offer CNC'd products for Lycoming Experimental engines. At this time, we have lightweight flywheels, lightweight valve covers, 14 to 18mm spark plug adapters, no-leak induction flange kits and dual fuel pump modules shown further down this page.

EFI in the Experimental aircraft world is becoming the new "normal" today. While some people cling to 100 year old technology such as carbs, mechanical injection and magnetos, the fact is our aircraft EFI/EI can do the job better, with less pilot monitoring and less maintenance. Reduced fuel flow for the same TAS is proven on several different engine types now and there is no chance of carb ice with EFI. Mechanical controls simply cannot match the optimized control that EFI/EI offers under all flight conditions from hot start idle to low MAP/RPM at high altitude to the pylons at Reno pushing 900hp.

We have been supplying the experimental aviation market with engine management systems now for over 25 years. We offer aviation specific software and hardware for popular experimental engines and we fly what we sell. We're involved as a supplier to several kit manufactuers, engine builders and our always ongoing R&D programs.

We've provided aircraft EFI and EI systems and ECUs for BMW, 3, 4 and 6 cylinder Suzuki, Continental, Lycoming, Franklin, Jabiru, LOM, Rotax, Saturn, Subaru EJ22, EJ25, EG33, EA81, EA82, EZ30, EZ36, Rotorway, Toyota, Hirth, HKS, Honda Fit, Honda V6, Rover/ Buick, Chev/ GM, Verner, VW, Jaguar and Mazda engines. These have accumulated an estimated 950,000 flight hours on hundreds of aircraft and military UAVs all over the world in the last 2 decades. Land based systems have accumulated millions of hours of operation under widely varied and sometimes severe conditions, including the famous Baja desert races with extreme heat, pounding G forces and punishing vibration levels. We've been flying an RV6A powered by a turbocharged Subaru EJ22 engine for product development purposes now for 19 years. We were the first to have a Gold Championship win at the Reno Air Races with EFI in 2010, 2018 and 2019. We have approval with the UK LAA on the Titan T51 (Suzuki and Honda V6 engines) and RAF 2000 gyrocopters and are working with customers in the UK on additional approvals for other experimental engine/airframe combinations. In April, 2017, we won the Best Design Award at the Mojave Experimental Fly-in.

SDS ECUs have a worldwide reputation for bulletproof reliability for over 25 years. Our competitors in this field have a tiny fraction of our flight hours and manufacturing experience. One will claim many systems flying but ALL of those were with re-branded, SDS supplied ECUs, not their's. As of Nov. 2025, we've sold over 2600 ECUs and systems for aviation applications- both civilian and military. In all markets, we've sold over 11,000 SDS electronic ignition and fuel controllers. These controllers have been real world proven in temperature extremes from -36C to +52C and have been lab tested for continued operation even after high voltage discharges directly to the ECU case. Our conformal coated circuit boards resist humidity and moisture unlike many competing products.

Racetech/SDS simply has more aviation experience with EFI on a wide variety of engine types than any other company and is the leading supplier of aftermarket EFI/EI ECUs/systems for experimental aircraft worldwide. We were the first company to manufacture dedicated, dual redundant EFI/EI ECUs, which are easily cockpit programmable, specifically designed for legacy, Experimental aircraft engines.

Please be aware that there are numerous variations among engines of the same type. Some parts may not fit or may have to be modified in certain cases.

Please note that all SDS electronics operate on 12/14 volts. 28V systems must use a separate 12/14V system or a step down power supply to power the SDS and fuel pumps.

Turbo

Subaru powered RV6A and RV7. Both equipped with SDS engine management

systems. The yellow RV6A is our company test aircraft. 20 years and over

460 hours on it now. We take our customer safety seriously so we feel

it's important to flight test SDS products ourselves before we release

them for sale to you.

Turbo

Subaru powered RV6A and RV7. Both equipped with SDS engine management

systems. The yellow RV6A is our company test aircraft. 20 years and over

460 hours on it now. We take our customer safety seriously so we feel

it's important to flight test SDS products ourselves before we release

them for sale to you.

Video of these planes in formation

Reliability has always been our first design criteria. Along those lines, we've never used marginally rated electronic components so nothing is ever working close to temperature, voltage or current limits. This is one major reason why SDS ECUs have such a good reputation for reliability, even in harsh environments. We also keep wiring connections to a minimum. More connections and intermediate plugs simply add potential failure points. Wiring harnesses are not something which need to be removed frequently. Finally, we believe the systems must be easy to use and understand. We give you the features you need and ask for to make the engine run properly and efficiently without useless frills or complicated programming. Aircraft engines are essentially constant rpm and load devices, spending the majority of their lives at fixed power settings for long periods of time. Once a power setting is established, the injector on-time and ignition timing remains the same until power is changed. For this reason, we feel that 3D mapping offers no useful benefits, it merely complicates understanding and operating the system for most people.

We are proud to be long time Gearheads, being directly involved in aviation since the late '70s and Experimental building and flying since the late '90s. We like to see our customer projects fly because we've been down the same path and it's very satisfying to see your long hours come together into an airplane you can enjoy.

We pledge to give you the best service in this business with immediate email replies, straight facts, no BS, no evasive answers, no sales pitches, no trash talk. We'll give you the same level of service both before and after the sale. We want you to be happy with your purchase so you tell others. That's how we've been the leader in this field for over 30 years.

Andrew Findlay won the Sport Class Gold championships in 2018 and 2019.

SDS is the only EFI system to have 3 Reno Sport Class Gold Championships.

Andy won the Airventure Cup race in 2023. Fastest overall, even over turbine powered aircraft. Congrats Andy!

Andy wins the 2025 Unlimited Class in Airventure Cup race with SDS EM-6

burning VP UL100E unleaded avgas.

Mark Smith's super clean RV-8

Les Kearney's RV-10 with dual ECU EM-6 system

Ales Baumrukr's immaculate Christen Eagle in the Czech Republic

Tom Hodgson's incredible B29 relica. SDS EM-5 equipped. Honda Fit

powered.

https://www.youtube.com/watch?v=iZQyTTQLI10&pp=ygURYjI5IHJlcGxpY2EgZmxpZXM%3D

Carlos Lopez's beautiful Lancair Legacy, Argentina. Dual CPIs.

See multiple CPI installation and aircraft photos here

Krea Ellis' award winning RV-10

David Shykula's Turbo Honda powered BD-5.

Tom McNerney's Lancair Legacy at Reno 2023. CPI-2 equipped.

Tim Wall's beautiful Spitfire replica. CPI equipped.

Tim Slater's Glasair at Reno 2023

Joe Corragio's Lancair Legacy at Reno 2023

Ivan Kristensen's award winning RV-14A

Go-EZ Aerobatics- Kyle Fowler.

Steve Brault's super clean Glasair Sportsman with IO-390 and SDS EM-5

Beautiful RV-14A in Australia equipped with CPI-2 ignition. 186 KTAS

cruise.

Maurice Castonguay's beautiful RV-9A

Marvin McGraw's immaculate RV14. Reserve Grand Champion kit homebuilt

2018 SNF. Dual EM-5 4F.

Andrew Findlay's Lancair. Dual EM-5 6F

Ray Watson's LS3 powered Moose

Murray Kester's very clean Spitfire replica. Jabiru 5100 powered.

Rusty Crawford is one of our highest time aviation SDS ECU customers (over 2000 hours).

Honda V6 powered Titan T51B replica built and owned by Ben

Chester-Master in the UK. Dual SDS EM-5 6F ECUs

Dave Anders' record breaking RV4 now fitted with SDS EM-5 4D system

Dan Kidd's LOM powered Glastar with CPI.

Steve Murray's IO-540 powered RV-10.

If you're considering an EFI or EI system for your engine, our recommendation is to evaluate all your choices in the market. There is no "best" system for everyone or every application.

1995: First SDS ECUs fly on Suzuki

1996: SDS flies on Continental O-200

1997: SDS flies on Lycoming O-320

1999: SDS runs on Jabiru engine

2003: SDS flies in our company RV6A demonstrator

2006: SDS introduces 3 1/8" aviation panel mount programmer

2007: SDS runs on Rotax 912 engine

2008: SDS supplies bolt on EFI kit for Rotax 912 engines

2008: Titan Aircraft selects SDS for their V6 powered T51 replicas

2010: SDS is first EFI system to win Sport Class Gold championship at

Reno

2012: SDS UK LAA approval for Suzuki V6 Titan T51

2013: SDS supplies its 1000th aviation ECU

2013: SDS UK LAA approval for Subaru EJ/ RAF 2000 gyro

2014: Introduces aviation CNC'd parts line including dual fuel pump

module

2015: Introduces redundant aviation ECU and dual access programmer

2015: Introduces CPI stand alone ignition system

2016: SDS UK LAA approval for Honda V6 Titan T51

2016: We introduce our own CNC'd 45 and 80MM billet throttle bodies

2016: SDS introduces world's first cockpit adjustable individual

cylinder fuel trim option

2016: SDS includes ignition advance switch on EM-5 and CPI for LOP

operation

2016: SDS introduces direct fuel flow output option, eliminating

mechanical flow transducers

2016: We introduce direct, head mount injector bosses for PV and AV

Lycoming engines

2016: We introduce baro compensation, LOP switch and new gauge mode

select features

2017: Racetech/SDS wins the coveted Best Design Award at the Mojave

Experimental Fly-in for the EM-5 and CPI. April 15th.

2017: We introduce bolt on EFI/EI kit for Continental O-200 engines

2017: We introduce adjustable brightness and contrast control for the

panel mount programmer

2017: We introduce bolt on EFI/EI kit for Continental IO-550 engines

2018: SDS wins the Reno Sport Class Gold championship again

2019: We introduce CPI-2 ignition system

2019: SDS wins the Reno Sport Class Gold championship a 3rd time

2019: We produce new 40 and 60mm billet throttle bodies making our

complete line billet

2019: We introduce the space saving Design1 aviation programmer with new

features for EM-5/EM-6 ECUs

2021: We introduce FAB kits for Van's aircraft, using SDS EFI

2023: 6th generation ECU introduced, with optional card data logging,

programmable closed loop, new diagnostics, 5th gauge mode, new LOP

functions

2023: B29 replica flies with 4 SDS ECUs

2024: We introduce black on grey LCD option for Design 1 programmer

As of late 2019, we've supplied the EM-6 Design1 programmers. Designed

to fit above the center stack and integrate better with modern glass

panels, these measure 6.25 inches wide and 1.47 inches high. LOP and

programmer select functions are now integrated on the keypad as well and

the fault warning LED. All EM-5 ECUs can drive these new programmers with

a V32 software re-flash to the ECU(s).

Rear of programmer. One serial cable connection for each ECU board.

Programmer can access either ECU board.

Design1 programmer integrates well with modern glass panel layouts.

Many aircraft engines have poorly designed intake manifolds with different runner lengths, different entry angles and small plenum volumes. This usually results in unequal airflow to each cylinder and therefore unequal air/fuel ratios in each cylinder. This leads to roughness and the inability to run far lean of peak, since one or more cylinders gets to the lean misfire point before the others. EGT spreads of over 200F are not uncommon. There's little you can do about it with a carb and the old fashioned way of correcting it on antiquated mechanical injection systems was with tailored nozzles but this can only work well at one rpm and power setting. Introduced in 2016, optional SDS V26-32 software allowed users to trim the fuel amount +/- 20% in 1% increments to equalize all cylinders AFR and EGTs, from the cockpit, in less than 30 seconds, as shown in the photo below:

To change your AFRs in flight, check your engine monitor EGTs and call up these windows in your SDS programmer. Increment or decrement fuel trim with the +/- 1 buttons, scroll left or right to the next trim window with the < or > buttons. It's that simple and makes screwing around with changing nozzles a thing of the past. You can also trim fuel at any throttle angle, MAP or rpm so you are not stuck with an imbalance like you are with mechanical systems. LOP operation is now fully optimized for best power, smoothness and fuel economy and near zero GAMI spread.

Flight testing allowed one user to get all cylinders to peak simultaneously and the engine would run smooth right to 200LOP. An 11% trim variation between leanest and richest cylinders was required.

Available for 4 and 6 cylinder engines. 6 cylinder systems require dual ECU boards for this function.

Not applicable to EM-1 to EM-4 ECUs. EM-3 through EM-4 ECUs can have an EM-6 board installed to get this capability. Older EM-5 ECUs can be upgraded to this capability for $300US. Simple wiring changes are required on older models to take advantage of the fuel trim software, matching ECU output pins to specific injectors.

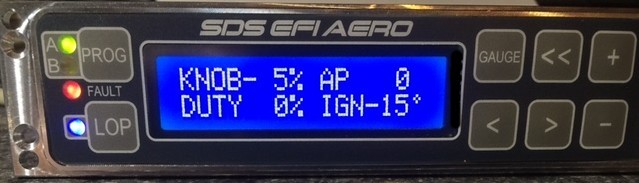

SDS pioneered the one switch leaning and ignition advance feature back in 2016. This allows you to instantly go LOP and simultaneously advance ignition timing to optimize power and fuel economy running at lean mixtures with their slower flame speeds. Both settings are user programmable:

Fuel leaned 24%

Ignition advanced 4 degrees while LOP switch is activated. MAP

protection negates this advance for safety above a user programmable

point.

Available since 2016, SDS provides a digital fuel flow signal to input into your glass engine monitor. Eliminates mechanical flow transducers. All internal, no external boxes and accurate across the entire rpm and load range.

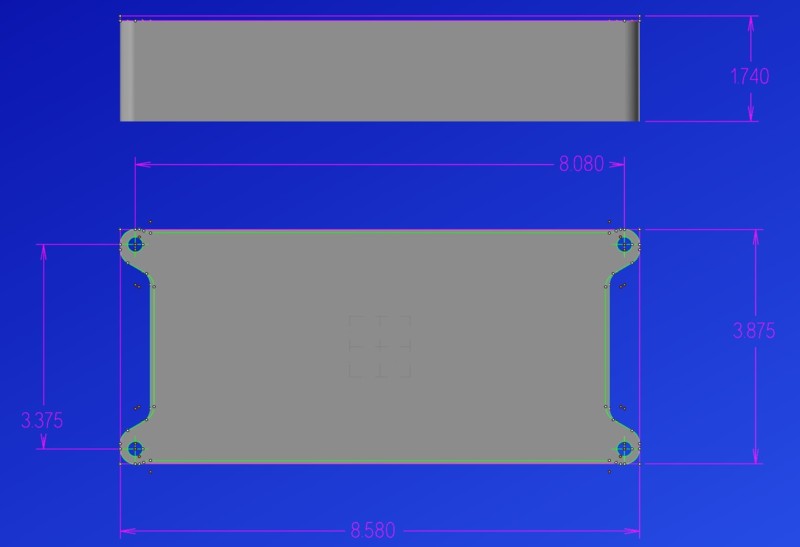

Basic ECU Specs

Size- 8.5 X 4.0 X 1.0 inches/ 22 X 10 X 2.5cm

Weight- 16.2 ounces/ 460 grams (single)

Current draw at 14V- 0.04 amps (no programmer), 0.06 amps with programmer plugged in

Dimensions for dual ECU

New updated optional Design2 aircraft 3 1/8 panel mount display head (backlit). Has 5 gauge modes to display, manifold pressure, rpm, engine temperature, induction temperature, battery voltage, fuel flow, injector duty cycle, throttle position, acceleration enrichment, mixture knob position, ignition timing and O2 sensor AFR. Also displays error codes for sensor failures and allows full programming of the system in flight. Updated with all the Design1 programmer features with integrated ECU access button, LOP button and internal fault lamp.

Because people often want different parts or to delete some parts from kits, we cannot put every combination with pricing on our website. Please contact us so we can finalize what parts you want, wiring harness lengths, preferred terminations and shipping costs: E-mail:racetech7@proton.me (Phone 403-671-4015). System prices range from about $1200US for four cylinder fuel only control with no other hardware such as pumps and injectors, up to about $7800US for a 6 cylinder Lycoming system with dual ECUs, dual ignition, all hardware such as injectors, mounts, coils, plugs, adapters, wires, throttle bodies, data logging, fuel flow and fuel trim options.

To place your order, it's best to email or phone us to discuss your project as each system is custom made and tailored for each client. We'll get a list of all your details, discuss wiring lengths, colors, options etc. and then quote you. You then pay by Visa or Mastercard, wire transfer or E-transfer for Canadian customers.

Phone 403-671-4015

E-mail:racetech7@proton.me

Disclaimer

These products do not conform to any recognized set of standards or certifications for aviation applications.

This ECU is not waterproof and will not function as designed if moisture invades the enclosure or power/ ground connections are interrupted. Failure of this unit may result in a complete loss of engine power.

Use of these products on amateur built/ experimental aircraft is at the discretion of the buyer who accepts full responsibility for any consequences resulting from its use. Since Racetech Inc. cannot control the installation, programming, application environment or use of its products, we accept no responsibility for damage, loss or personal injury resulting from the use of SDS products. By using SDS products, the user understands and accepts this.

If any user does not agree to this disclaimer, they may return the system/ parts in new condition for a full refund.

Dual EM-6 ECU with Design1 programmer and card data logger module

New 112 pin CPU

Data logging to a data card now in addition to the original Windows laptop/ tablet. Uses an updated version of SDSDash to view and manipulate data.

Users will be able to reflash the CPUs themselves to update software in future which will speed things up and eliminate the shipping hassle.

Capability for a switch to retard timing when using different fuels- ie Mogas vs. Avgas.

User programmable automatic closed loop mixture control running off a wideband O2 sensor. This is intended mainly for unleaded Avgas and Mogas use.

O2 sensor power relay/ delay/ diagnostic features.

Several new self diagnostic/ test features.

Upgraded software to negate sensor failures.

5th Gauge mode.

PWM output capability.

Future CAN BUS capability. Hardware on board and pin connections done.

Some other minor features and behind the scenes stuff that user feedback suggested.

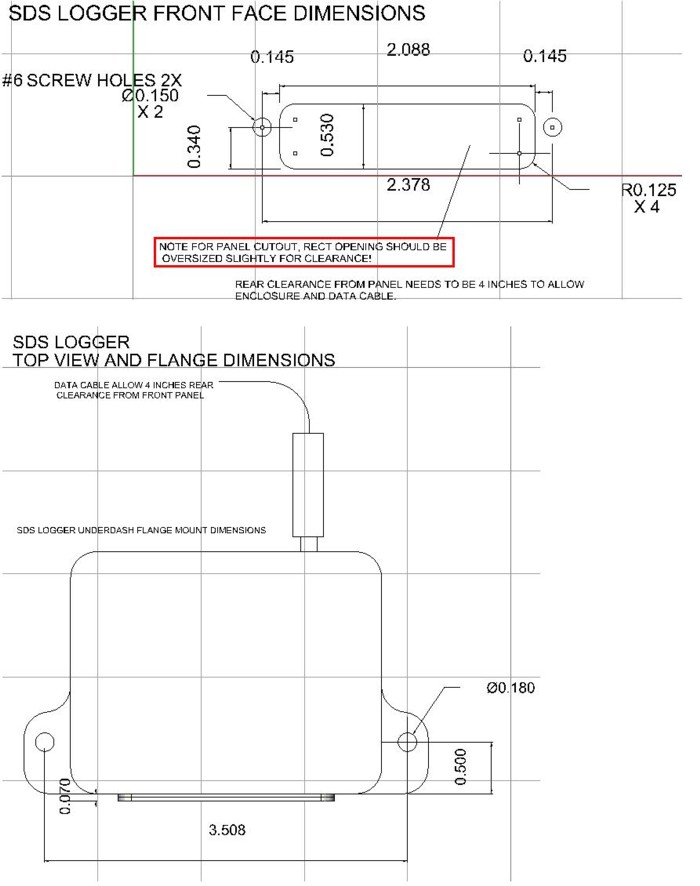

This is the EM-6 slim style programmer we call Design1, intended for

glass panels with limited space to mount the round style. It's designed

to mount either above the center stack in the panel arch area or below

the radio stack. Size is 6.25W X 1.47H. You need about 4 inches behind

the panel to mount and get the data cables turned. This incorporates the

programer select and LOP function on the keypad to eliminate these

external switches previously used on the EM-5 systems. Programmer is

compatible with EM-5 ECUs which have been re-flashed with the latest

software. The fault light on the keypad also replaces the external one

previously used.

New black on grey transflective display option for Design 1 programmers.

This offers better sunlight readability when the programmer is placed

well below the glare shield or for aircraft with bubble canopies.

Rear view

This is the new EM-6 external card logger box which can be through panel

mounted or under the edge of the panel flange.

Mounting detail

EM-6 Aviation Manual (updated Dec 2/25)

We can reflash earlier EM-5 ECUs to the latest version of EM-5 software. Cost is $80US plus shipping. You must send your ECU in to us.

V26/32 contains options for 100 rpm increment programming (no charge to activate)and individual fuel trim control, $300 charge to activate.

V26.1/32 added to the new fuel trim capabilities, a fuel flow signal output option to emulate FlowScan/ Red Cube type fuel flow meters for glass engine monitors. This is a $100 option to activate and provide an additional pin and wire on EM-5s.

PC data logging can be added to your V25 to V32 equipped EM-5 ECUs for $110 ($135 if you don't have the round data port hole in your ECU case). We need your ECU back to us. The card logger option can't be used on EM-5 or older ECUs.

Return shipping charges apply in all cases.

While there are many automotive engined homebuilt aircraft flying with the OE computer controlling fuel and ignition successfully, many users may not be aware of some potential pitfalls of using these systems. OEM computers can either shut off the injectors if certain things fail such as a water temperature sensor to protect the engine from a perceived or real overheating condition or go into a very low power limp home mode. Either of these scenerios mean that you are coming down in an aircraft. The designers of these automotive ECUs did not take aircraft use into account during the design phase obviously. Their considerations were likely as follows, in order of importance: 1. Reliability- keep the engine from destructing ( shut the injectors off if necessary), 2. Emissions, 3. Fuel economy, 4. Driveability, 5. Power. Fortunately modern EFI systems, sensors and ECUs are very reliable, generally speaking. Just be aware, that as on your Continental or Lycoming, anything CAN fail equally so on your automotive/EFI conversion, making you an unwilling glider pilot.

Many people have spent countless hours trying to unravel programming code on OEM ECUs for use on aviation applications, to undo unsuitable code or responses or security interlocks sometimes successfully, sometimes not. Others wonder what the ECU might do when certain sensors or inputs are modified or disconnected, especially many of the tied in chassis sensors on modern systems, not to mention security and digital key interfaces. What some people have attempted to do in dozens or hundreds of hours with often unknown consequences using OE ECUs can generally be done in minutes with SDS. You know exactly what the system will do without any hidden secrets or repercussions. All automotive OE ECUs were designed to use an O2 sensor for closed loop feedback of the air/ fuel ratios at part throttle. As such, they may not be very suitable for use with leaded avgas. SDS does not require an O2 sensor at all.

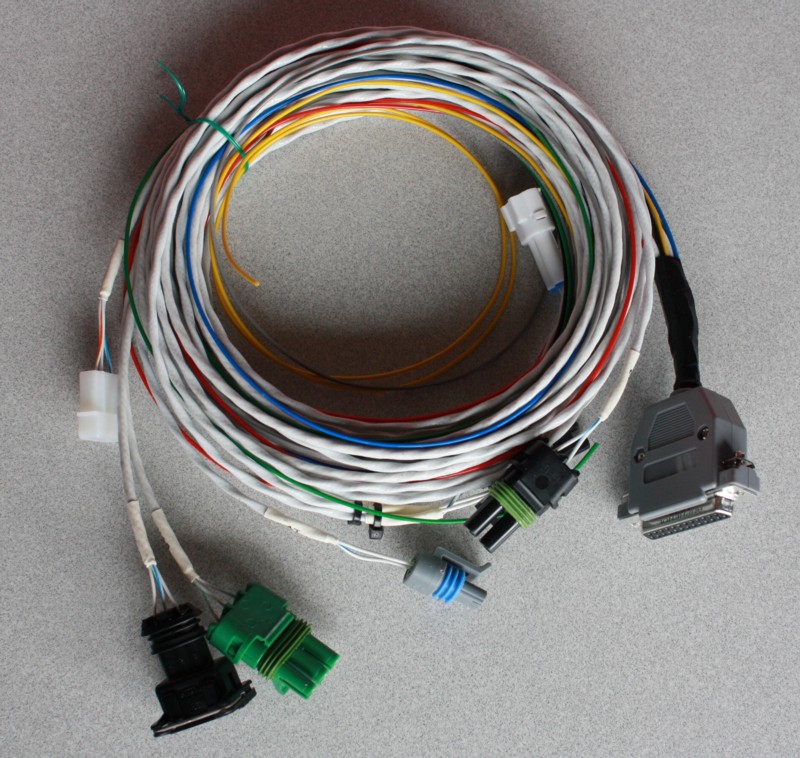

People using OE automotive systems often have to use the factory car wiring harness which obviously was not designed to fit their airplane. They try to strip out wires which are not needed, lengthen this, shorten that. Usually they just have a big, stiff, heavy, ugly mess on their hands. With SDS, we build a custom length, lightweight, reliable harness for your installation from Mil Spec Tefzel. We can leave connectors off for easier firewall passage and can even provide a harness with no pins on so you can custom tailor each cable yourself.

Typical auto OE wiring harness

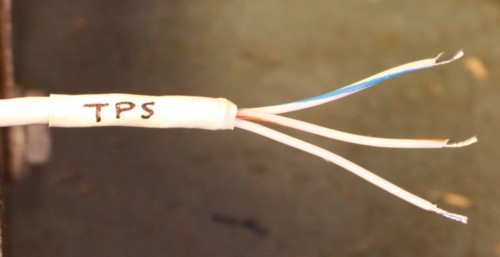

SDS Tefzel wiring harnesses. We can terminate or leave connectors off

for tailoring lengths and easier firewall passage.

Each cable marked for sensor

Proper strain relief and insulation is imperative for reliability.

We highly recommend that all EFI harness wires be run separately from other wires which carry high current/ voltage or any type of pulsing current signals. It has been shown that wires run parallel to each other in this fashion can lead to EMI and inductance coupling which may cause ECU running problems. Generally run the EFI wires through one side of the firewall and all other wires through the other side.

The big disadvantage of EFI compared to a carb or mechanical injection and magnetos is that electrical power is required for the pump, computer, ignition and injectors. The likelihood of both the alternator and battery failing simultaneously is practically zero with standard aircraft maintenance procedures. Generally, a good battery will allow you to keep essentials powered for 20-60 minutes after an alternator failure permitting diversion to another airport. Many people prefer to also have a second battery and/or alternator which we encourage. We consider proper gauges and/or warning lights to indicate an alternator failure to be very important.

Virtually zero maintenance, lower fuel flows due to better mixture distribution, automatic mixture control, no carb heat, no more hot start issues, smoother running, no mag checks, no live mag issues, longer engine life due to proper mixture control and less bore washing are some of the major benefits of EFI.

1. We have far more experience than any other company in this field with

an unmatched track record on many different engine types including the

2010, 2018 and 2019 Sport Reno Gold Championship winners. We've produced

over 2300 ECUs and systems for aviation to date, starting back in 1995.

We constantly evolve and improve, now on our 5th generation of ECU and

working on the 6th generation now.

2. Our basic designs are also used in many automotive applications so we

have a huge amount more hours (millions) to quantify reliability than

aviation-only systems.

3. We fly what we sell and the aviation market is now our primary

one.

4. Our systems are designed to keep the engine running at close to full

power even with multiple sensor failures unlike many other systems which

may shut the engine down or OEM automotive systems which will go into a

limp mode, not allowing enough power to maintain flight.

5. We have the best tech and customer support in the industry.

6. We design and build most of the parts and write all software in-house

so we know everything about it.

7. Systems are individually tailored for your engine with realistic base

programs and custom length wiring harnesses (either terminated or

unterminated for easier installation and firewall passage). You won't

struggle making wiring or trying to start your engine like with many

other systems which just come in a box. We can build wiring in Tefzel or

PVC. With many different airframes out there, we don't believe in

Cookie-Cutter, one-size-fits-all. You should get exactly what you

want.

8. We don't use El Cheapo components like some other brands pretending

to be aviation quality.

9. We offer many new features that other brands don't, plus CNC machined

and annodized components striving for low weight with high durability

rather than scabby bare cast parts.

10. We listen to customer feedback and incorporate many of these ideas

to improve our products on a constant basis.

11. We are conducting R&D on a constantly ongoing basis and

innovating new features and new products to improve our product

capabilities and depth of product line.

12. We offer you solid, technical information on our products, not

shallow sales pitches, evasive answers or BS.

13. Better value for your money- more features, higher quality, lighter

weight, customized for your project.

14. We use superior materials in high stress areas like the thread-in

injector mounts while our competitor uses poorly designed, crack prone

parts.

Q. What about redundancy?

A. On twin plug engines, it is posible to retain one mag and add a fuel

nozzle into the plenum as a backup. For pilots who are not comfortable

with this idea, we can offer dual ECUs. The dual ECU can also be used on

automotive V8 and V12 engines in a split bank configuration, with one ECU

running one bank of the engine each. We treat a V12 as two, six cylinder

engines sharing a common crankshaft. Each ECU would have it's own sensor

suite.

Q. How about low voltage conditions after an alternator failure?

A. The EM-6 ECU will continue to operate down to 7.3 volts as shown in

the photo below when most other electronics and avionics have given up

the ghost at around 9 volts

Q. What fuel system mods might my aircraft require with SDS EFI?

A. Most aircraft will require return lines to the tanks and a Duplex

fuel selector with both feed and return ports as those sold by Andair.

Q. What use is the mixture knob on an automatic aviation system?

A. We recommend the mixture knob be panel mounted in all aircraft to

allow the pilot to make a mixture adjustment in case of certain sensor

failures. This gives you independent control of the mixture from the

programmer. Some pilots prefer to manually lean with the knob once cruise

power is set also.

Q. How do I start to tune SDS on my aircraft?

A. All systems have a base map entered if we know your injector flow

rate and engine displacement. The engine should start and idle for you

first time. The mixture knob allows instant mixture adjustment +/- 50% so

you can get a smooth idle right away while the engine warms up. By using

a wideband air/fuel ratio meter kit which can display the AFR directly in

the SDS programmer screen. you can observe and correct the AFR at each

rpm point with the aircraft tied down while slowly advancing the

throttle. Main programming only takes about 10 minutes for most engines.

Programming for cold start can take longer as you must have the engine

cold at each engine temperature to be able to observe and correct the

values. The EM-6 offers optional full data logging to a Windows device or

logging directly to a memory card for review after the flight.

SDS 40 micron pre and post pump fuel filters with replaceable SS

elements. 2 sizes available (small is 3.55 X 1.5", large is 4.75 X 2").

We also stock top quality Aeroquip, Earls and Goodridge fittings and

hoses.

Genuine Walbro/ TI pumps, made in USA

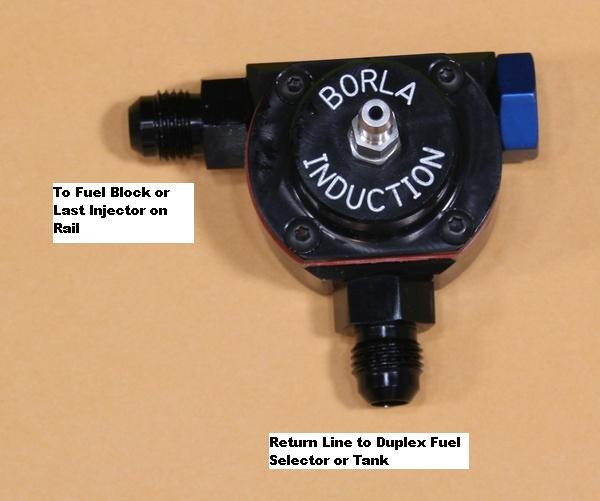

Detail for fuel line hookup on Borla fuel pressure regulator. Made in

USA.

Racetech dual pump module. Mounts twin genuine Walbro pumps. Anodized

6061T6 body resists oxidation and corrosion, 7075T6 fittings are double

O-ring sealed (genuine Viton) for ultimate strength and reliability,

straight flow path without restrictive banjo fittings. Mounts drilled for

AN3 bolts- unthreaded, a variety of 1/4 NPT ports available for different

fuel line connections and pressure measurement, stainless steel hardware.

Price $690US with pumps for up to 300hp. $750 US with pumps for up to

400hp. Weight as shown is 2 pounds 11.8 oz. Supplied with 4 1/4NPT plugs.

No dealer discounts on these items. This is our original design and

others have copied it now. Compare our pump module to our competitor's

design which puts the fuel connections under mechanical stress when

mounting.

Please note that we do not tighten or seal the side pipe plugs on the pump modules. All other parts tightened and ready to go. Screws are Locktited.

Service Parts for Racetech Fuel Pump Module

-3 crush washers for pump to hex adapters- Earls 177003ERL

Filter element for older pump modules- Earls 230107ERL

O-rings for small hex adapters- Viton V75 012

O-rings for large filter hex adapter on older models- Viton V75 019

Note we use only genuine, made in USA Walbro pumps, genuine made in USA Borla regulators and US made filters and AN hardware- no cheap Chinese copies/ ripoffs. Body designed, machined and anodized in Canada. We support jobs and industry in North America as much as possible.

We can supply many individual components and kits for EFI/ EI conversions. We believe each installation is custom and will tailor systems to your individual needs. Because of the variations in airframes and parts/ installation preferences we don't publish all kit prices here. It's better to contact us via email to work out what you want and need for your particular installation. We can quote you from there. E-mail:racetech7@proton.me

50 EM-5 ECUs awaiting final testing and shipment to a military aviation

customer

Recommended wideband kit for SDS is the AEM 30-0310. Commonly available at Summit Racing. The Ballenger V2 is no longer being produced and the V3 is very expensive. Please note that all wideband sensors require a dedicated controller. The sensor by itself is useless.

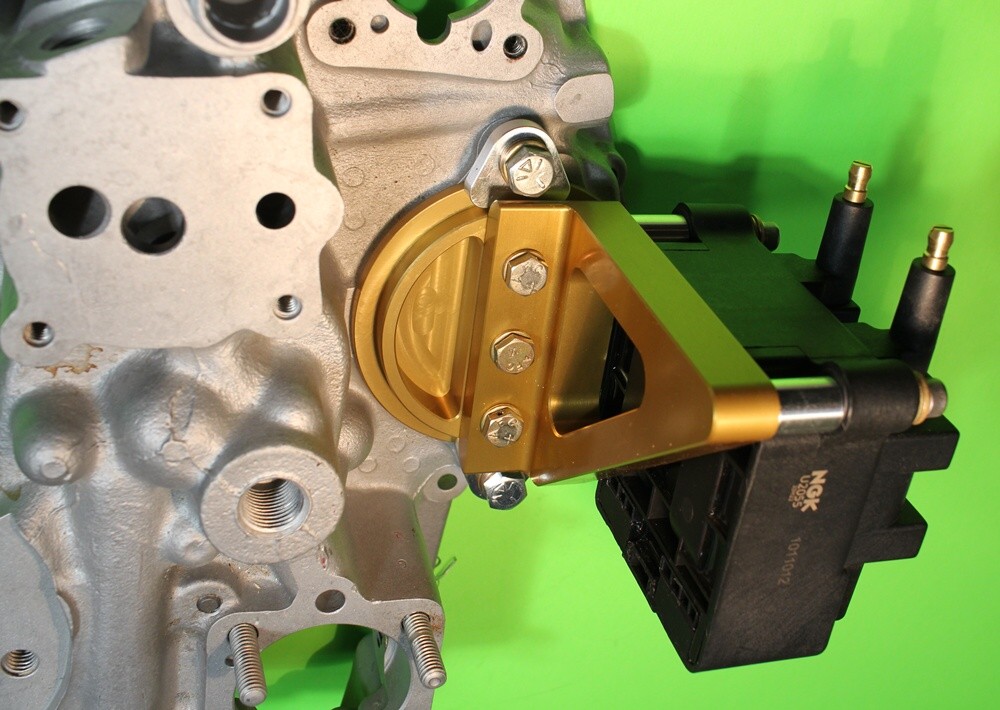

Gen 3 rear coil mount for 4 cylinder Lycoming engines.

Design 1 programmer in beautiful panel built by Nick Nafsinger in Texas

Les Kearney's RV-10

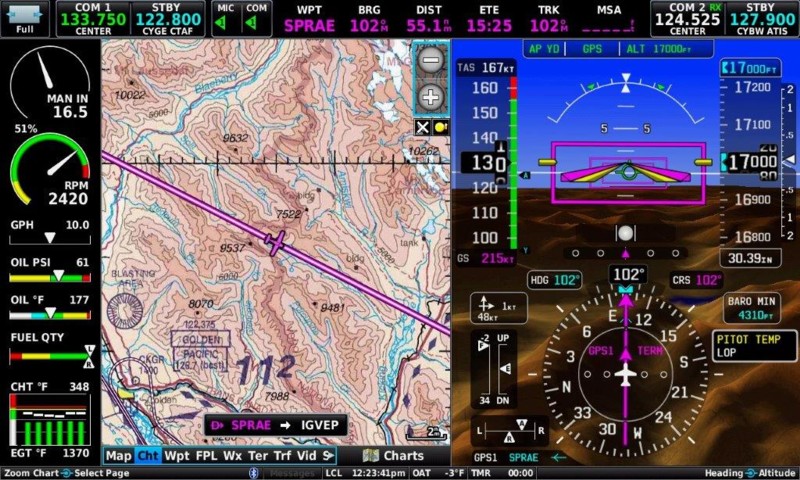

Screen shot from Les Kearney's G3X, RV-10. Corrected TAS 174 knots on 10

gph LOP.

Clean set of plugs from Les' RV-10 at annual

EM-6 Documentation

For the EM-6, we don't plan to provide printed copies of the main installation manual going forward. Digital copies are easier to search and you'll have the latest revisions available. This also frees up our time and helps keep costs a bit lower.

Refresh your browser tip, hold down your shift key while you click refresh to be sure you get the latest webpage

EM-6 Aviation Manual updated Dec 3/25

Maintenance and Inspection Schedule May 12/24

Lycoming 4 cylinder magnet mounting updated May 12/24

Lycoming 4 cylinder magnet mounting diagram updated Oct. 26/17

Lycoming 6 cylinder magnet mounting updated May 12/24

Using mag switch to control coil pack through a relay (schematic)

Dual 6 cylinder EM-5 wiring schematic, warning system, integrated with Garmin G3X Updated Dec. 28/20

Dual fuel pump integration with Garmin G3X

For main aero CPI installation and tuning manual click here updated April 4/22

For CPI aircraft supplement guide click here updated Mar. 20/22

Lycoming 4 cylinder magnet mounting updated Oct. 23/19

Lycoming 4 cylinder magnet mounting diagram updated May 12/24

Lycoming 6 cylinder magnet mounting updated May 12/24

Lycoming Tuning Guide PDF updated Mar. 20/22

EM-5 Aero Installation/ Tuning updated July 14/21

EM-5 Ignition Manual Lycoming updated April 7/20

EM-5 Ignition Manual Generic updated July 6/19

Aviation ECU DB pinouts updated Feb. 27/18

Dual 6 cylinder supplement/ wiring updated Nov. 20/22

Fusing/ switching schematic for dual ECUs (4 cylinder)

Fusing/ switching schematic for dual ECUs (6 cylinder)

O-200 Installation manual updated June 12/18

IO-550 Installation manual updated Jan. 12/19

Component current draws and breaker recommendations updated Nov. 7/17

How to mount injector bosses on intake tubes

CPI2 programmer panel drawing updated Mar. 15/18

CPI2 installation manual updated July 22/25

CPI2 hardware installation manual updated Mar. 20/22

CPI2 pinout list updated Nov. 7/19

Using mag switch to control coil pack through a relay (schematic)

Some useful tuning information here aimed towards Subaru installations but generally applicable to other auto conversions: Aircraft Engine Tuning Guide

Drilling Lycoming flywheel for mounting magnets

Basic programmer function, gauge modes, RPM Fuel, MAP Fuel parameters

Basic programmer function Part 2

Building your MSD plug wire set

Installing O-rings on SDS Lycoming valve covers

Explaining aviation components

Video on our SDS billet valve covers

Tutorial for drilling Airflow Systems A/C Flywheel with serpentine belt

To see all the videos on our YouTube channel, click here: https://www.youtube.com/channel/UCiyBZlgDHg2GvQfelECCGoQ

MSD Plug Wire Part Numbers

The following bulk PNs fit all coil packs:

34049 8.5mm red Superconductor wire

34615 90 degree terminal (plug and coil)

34555 90 degree coil boot

34515 90 degree plug boot

34605 straight terminal

34565 Straight boot (fits coils and plugs)

Recommended MSD plug wire crimping tool PN 35051

Pin Crimping Tool

For crimping most of the Weatherpack pins supplied with your system, you can order https://www.amazon.com/gp/product/B002CCAEJ6/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1.

Please note: our magnet mounting system for Lycoming engines is not compatible with the Sky Dynamics lightweight flywheels.

More info here: CPI

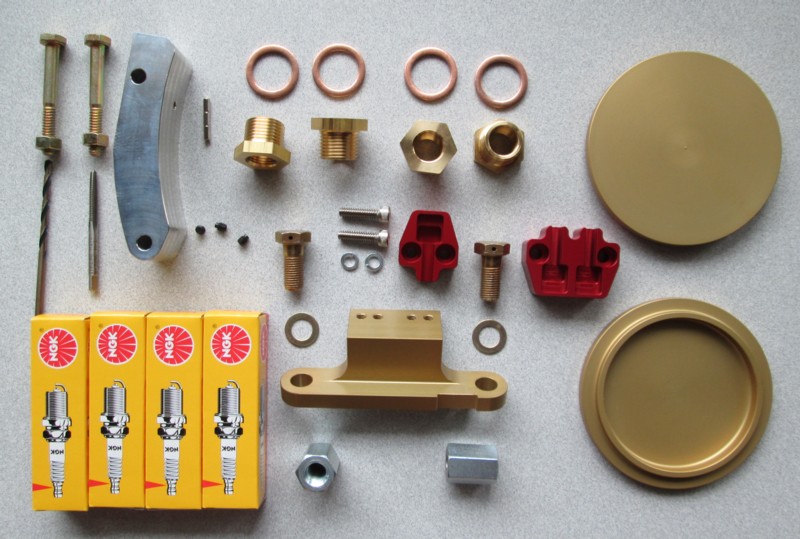

Lycoming 320/360 ignition kit includes Magneto cover(s), single or dual

Hall sensor and mount, hardware, automotive plug adapters (1/2 reach) and

plugs plus drilling block, drill and tap to mount magnets into OE

flywheel, panel mount kit, MSD 8.5mm wire sets and wiring harness also

included (not shown). Fits engines with 9.75" OD flywheel only. Starts at

$1193US. Wiring harnesses can be custom tailored to your needs and any

items not desired can be deleted from the kit. Note, you must drill and

tap your own flywheel for the triggering magnets.

SDS Aero Products T shirt. Logo design by Elle Nguyen, our model here.

S, M, L, XL sizes available. Gray or white shirts available.

SDS Aero cap at the beach

Aero Sport Power is an authorized distributor for Racetech/SDS Lycoming

products

Website: aerosportpower.com

https://www.frankenkopter.com/

Frankenkopter supplies SDS EFI and turbo kits for Rotorway Helicopters

30 amps, 3 pounds, backup power system

Avionics supplier and custom instrument panel maker

For all your custom hose requirements

https://www.tsflightlines.com/

Racetech Inc.

#5-304 Noorduyn Park

Calgary, Alberta, Canada

T3Z 3S8

Phone 403-671-4015, Fax 403-453-7687

E-mail:racetech7@proton.me

CLICK ON LINKS BELOW: